08/04/2024 – Wire descaling treatments

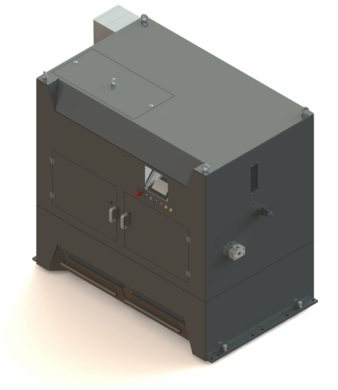

Rebar coating machine

The “Wet Coating Machine” by Witechs is the ultimate way to directly improve working conditions in customer production processes at low cost.

It has never been so important to bind personnel to enterprise. The best way to bind personnel is to offer outstanding working conditions. The revolutionary wet coating machine (WCM) is for inline-coating of cold-rolled steel wire (rebar). WCM eliminates dust during production. Speeds of up to 10 metres a second are achieved without any problems.

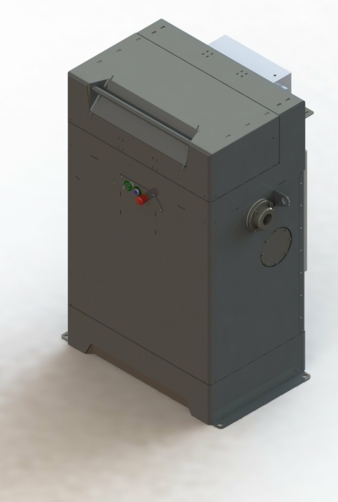

At Witechs all types of mechanical descaling can be found to best fit processes, all at the lowest possible operational cost. From low to high quality cleaning of wire rod, related of course to cost. Witechs has developed a new brushing machine. If traditional (simple) steel-wool descaling is not good enough or customers want to improve their quality and the belt-sander machine does not fit in production process, then the “WBE-4L” brush machine is the solution. This brush machine – with its operational cost price of less than €2 per ton – perfectly complements production processes. The service life of the brushes is up to 2,500t. The compact machine fits in pretty much any production line. It controls itself, making it a fully autonomous machine. This further reduces the risk of human error to a minimum. The machine itself indicates when the brush needs to be replaced, ensuring a consistent cleaning quality. Come and check out the new method for coating steel rebar and the latest developments in the area of wire descaling treatments during the “wire” in Düsseldorf.

wire 2024, hall 11 booth D 74

Witechs B.V.

Zirkoonstraat 7

7554 TT Hengelo (O)

The Netherlands

Contact person is Jort Kuipers

Tel.: +31 74 8510699

kuipers@witechs.com

www.witechs.com