19/08/2022 – Ningbo Orient uses Sikora’s “X-Ray 8700 NXT”

Quality control at the end of the CV line

Many submarine cable manufacturers, such as the Chinese company Ningbo Orient, rely on X-ray devices from Sikora for quality control in CV lines. In addition, producers of power cables benefit from the final quality control as it ensures the highest quality of the cables delivered to their customers.

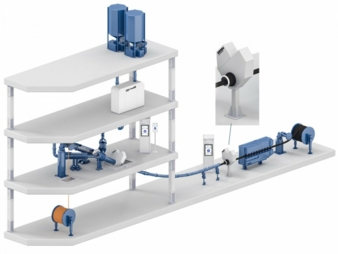

For a continuous and reliable quality control at the production of medium, high and extra-high voltage cables as well submarine cables in CV lines, Sikora’s “X-Ray 8000” product family has set standards with more than 1,500 devices sold worldwide. The systems convince by precise and reliable measurements of concentricity, wall thickness, diameter and ovality as well as by controlling cables with up to three layers.

While the “X-Ray 8000 Advanced/NXT“ provides information for a fast centering of the crosshead and an automatic control, the “X-Ray 8700 NXT” measures the final product dimensions (diameter, wall thickness, concentricity) at the end of the production line. It is applicable for cables with solid and stranded as well as Milliken conductors with single, double or triple layer insulation. The “X-Ray8700 NXT” is also suitable for quality control of insulation material based on polypropylene (High Performance Thermoplastic Elastomer – HPTE). The combination of the “X-Ray 8000 Advanced” at the beginning with the “X-Ray 8700 NXT” at the end of the line offers a precise determination of the shrinkage values for all three insulation layers. This assures an optimum process control for a perfect final cable.

Sikora AG

Bruchweide 2

28307 Bremen, Germany

Contact person is Katja Giersch

Tel.: +49 421 48900-0

sales@sikora.net

www.sikora.net