12/12/2018

Power pack for the production of stabilisers

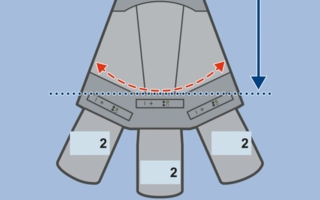

The CNC-controlled “RBV 60 HD” bends high-strength tube and solid material into stabilisers for car passenger cells. The maximum diameter is 43mm; the recommended length is 3,500mm. The maximum bending moment is 25kNm and the follow-up pressure force is 50kN.

The “RBV 60 HD” bends stabilisers, such as those used in SUVs and pick-up trucks, as well as tubes in safety passenger cells. It is CNC-controlled and currently the only left-right bending machine for stabilisers in diameters up to 43mm on the world market. The material up to 3,500mm standard length can be high strength, hollow or solid. Changing the 2.4t bending head is a fluid process.

The maximum bending moment is 25kNm, the follow-up pressure is force 50kN. The forces are not transmitted by belts but via gear sets. For this purpose, the housing was reinforced by stronger drive spindles. The clamping force was raised to 300kN using double slide rails. The bending forces are three times higher than the smaller “RBV 60 ST”, which bends pipes up to 35mm x 4mm and solid material up to 25.4mm in diameter.

The Wafios “Easy Way 3.2” programming system is installed in the machine. The 24-inch multi-touch screen features push functions such as start and stop buttons. The machine’s command centre is rounded off with a manual control unit with an integrated colour touch screen for selecting all functions in setup mode.

Optionally, the RBV 60 HD can be fitted with IQ functions such as “IQ Tube”. Unlike many tube bending machines on the market, the RBV 60 HD uses a simulation program that is integrated in the control system. The bending process is illustrated on the basis of the part geometry in conjunction with the tool design used. The design of the bending processes, possible collision areas as well as the required theoretical production times for the bending process are calculated. This makes it possible in the event of a collision to select alternatives in the simulation. As a result, this makes it both quicker and easier to achieve a collision-free bending process. In another new functionality, overbending is taken into account and simulated in relation to the material properties.

The result is fewer rejects in the machine setup, simplified and automated setup even for users with less experience, feasibility checks and detection of collisions before bending, determination of the theoretically achievable cycle time before bending starts and a reduction in the number of prototype tools.

“IQ Cockpit” enables the location-independent representation of machinery production data on PC or smartphone. Using WiFi or UMTS, it displays the machine status, the item currently in production as well as the unit performance compared to the nominal value. The display gives an overview of the current machine data and enables quick action.

“IQ Torque” detects both workpiece and tool breakage and stops the machine immediately or at the end of the cycle, depending on the setting. Possible damage to the machine and tools can thus be avoided. Quality-influencing process changes, such as fluctuations in the material quality of the workpieces, are identified by means of envelope and trend monitoring of the engine torque of individual machine axes.

Also integrated is the Wafios security system with design housing and surface laser scanner. This eliminates the need for space-consuming protective fences, which also make accessibility for maintenance and retooling more difficult. Conversely, the RBV 60 HD can be integrated into a fully automated cell with protective fences. The thus dispensable housing creates greater freedom for improved loading and unloading.

The machine is loaded in a cell behind the bending head. This saves time for positioning the feeder and does not clutter the space in front of the bending head. The loading height was designed to be as low as possible because heavy bars and tubes are also loaded manually. The RBV 60 HD is intended for use in the manufacture of top-range stabilisers, for example in SUVs or vans. The machine is also suitable for bending thick-walled, high-strength pipes in roll bars and A-pillars used in safety passenger cabins.

wire Russia 2019, Forum / C52

Wafios AG

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0