13/02/2020

Powder coating machines

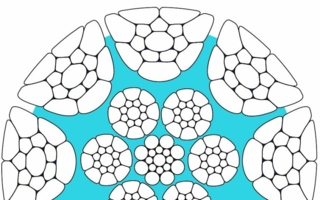

Maschinenbau Bardowick GmbH has been producing powder coating machines with and without electrostatics for worldwide use in the cable and rubber industry for decades. These machines are also used in cable and rubber strip production to apply powdered release agents to the product surface.

Machines from Bardowick are particularly characterized by a patented filter cleaning system, which ensures that no powder is emitted when the filter elements are cleaned and that the environment is not contaminated with powder. At “wire” 2020 the company will demonstrate their successful powder coating machines in operation.

The demonstrated powder coating machines show the variety of possible uses. If there is not enough space in the extrusion line, the coating chamber can be operated separately from the main machine. Their machines are easy to move between the extrusion lines. A quick and easy height adjustment of the coating chamber to the extrusion line height is able to be realized without tools. All process-relevant parameters such as pressures, electrostatic settings, status of the monitoring sensors can be transferred to the higher-level line control via your favourite fieldbus technology. For special applications, Bardowick has provided a separate, fully-fledged control panel so that customer employee is able to operate the powder coating machine from a distance even without a higher-level control system.

Powder application detection station

Bardowick is presenting a new type of inline monitoring system, which controls the powder application and visually informs the operator in the event of malfunctions so that countermeasures can be initiated. The times of uncontrolled powder application are a thing of the past.

Automatic powder refill unit

In the past, external powder refill containers were used for the automatic filling of the powder coating machines. The operator had to open a paper bag in order to carefully fill the powder into the refill container. Powder emissions and the associated contamination of the environment could not be avoided. Their newly designed powder refill container has the following advantage. The operator simply places the closed paper bag in the refill container. A corresponding lance is inserted from the outside into the powder sack, through which the powder is automatically conveyed to the powder coating machine if required. There are no more powder emissions; the environment remains free of powder contamination.

Maschinenbau Bardowick GmbH

wire 2020, hall 14 booth G 16

Langenkamp 7, 21357 Bardowick/Germany

Contact person is Dieter Eberhard

Tel.: +49 4131 6033-13

eb@mb-bardowick.de

www.mb-bardowick.de