14/03/2025 – Safety concept for manual product guidance

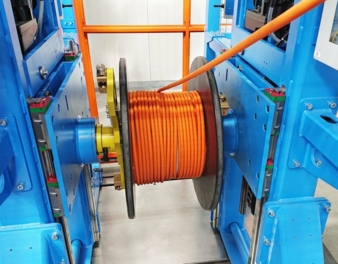

Portal payoff with remaining length operation mode

Kurre Systems, a German company renowned for its custom solutions in mechanical engineering for the cable and wire industry, is enhancing its portal payoff with a new "remaining length" operation mode. This innovation significantly improves both safety and tool-free machine setup.

“In certain production and process steps, it is unavoidable to enter the winding area. However, from a safety perspective, this presents a challenge. Kurre Systems now offers an optimized payoff specifically designed for such cases,” explains René Püschel, Sales Engineer at Kurre Systems. Thanks to a special safety concept, the machine can now be safely entered during operation to manually guide remaining lengths.

Remaining length operation for sustainability and flexibility

By intentionally activating the mode with a key switch, the machine is set to “Remaining Length Operation”. In this mode, the system adjusts to predefined parameters and aligns with safety requirements: the rotational speed is reduced, the traversing movement is stopped, and the pulling forces are limited. “In this state, the operator can perform tasks within the machine. This is made possible through the use of safety assemblies that ensure redundant protective mechanisms,” René Püschel adds.

This developed operational mode increases flexibility and sustainability in cable production without compro-mising safety. Particularly, the waste of the last few meters of usable length – for example, due to mechanical influences – is eliminated by manual guidance. Delicate products can also be precisely processed to the very end. As a result, this process avoids significant amounts of production scrap while simultaneously increasing efficiency.

Optimal safety and tool-free setup

Another key component of the safety concept is the integrated machine guard, equipped with bumper strips (switch contact strips) that are also secured with fail-safe control assemblies. In the event of a collision with an object or person, the strip ensures an immediate stop of the traversing movement without halting the wind-ing process. Additionally, the absence of fixed fencing during winding operations without traversal results in considerable space savings.

“Kurre Systems is known for providing 'small' solutions with a big impact, and this is particularly evident in the tool-free machine setup,” René Püschel highlights. Both the pintles, the take-up bar, and the take-up pins can be exchanged with just a few simple steps, without any tools. Spare parts with complementary sizes are conveniently stored directly near the work area.

Technical Specifications

In addition to these technical innovations, the winder impresses with its versatility. It safely processes products with diameters ranging from 1.0mm to 22mm and is designed for spools with the following specifications:

Flange diameter: 400mm to 1,600mm; width: 250mm to 680mm; weight: up to 4,000kg.

Kurre Systems

Industriestraße 5

26683 Saterland

Germany

Contact person is Thorsten Wilde

Tel.: +49 4498 9250-0

thorsten.wilde@kurre-systems.de

www.kurre-systems.de