09/04/2024 – The new drum spooler from Kurre Systems leaves no wish unfulfilled

Perfectly winded, foil-wrapped, labeled and palletized

In the further development of the drum spooler, Kurre Systems has gone several steps further and now offers its customers a system that outputs a perfectly winded, foil-wrapped and labeled spool onto a pallet fully automatically every 90 seconds or 500 meters.

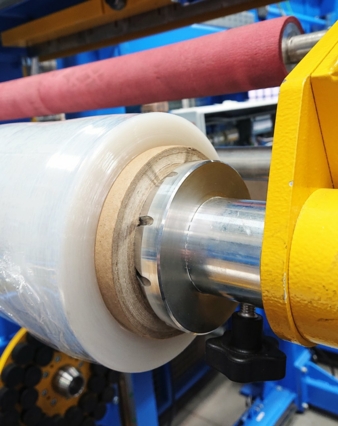

The ingenious feed-in mechanism guarantees that the product ends are automatically clamped in the spool core for fully automatic overlapping at full line speed. © Kurre Systems

The 4-axis palletizing head with integrated suction unit transports spools horizontally or vertically and supplies the labelling station as well as the palletizing station (separated into completed spools / faulty spools). © Kurre Systems

The ingenious feed-in mechanism guarantees that the product ends are automatically clamped in the spool core for fully automatic overlapping at full line speed. © Kurre Systems