03/04/2024 – Cable manufacturing

New machines, services and bows

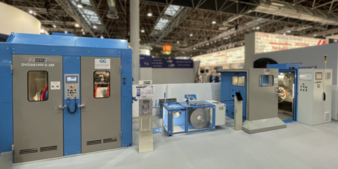

Setic, manufacturer of special, data communication and LAN cables machines and a major actor in the automotive wire equipment will exhibit and welcome visitors and customers in its booth at “wire” together with Pourtier, C2S and Bow Technology.

The “wire” in Düsseldorf will have Setic as its participating wire and cable, which is well-known for its special, data communication, and LAN cable machines, and also provides solutions for automotive wire equipment globally. World technological developments in the automotive industry such as all-electric cars, encourage Setic to enhance its high-speed double twist bunchers, single twist take-up with backtwist pay-offs and stranders solutions for application such as EV charging cables, battery cables and data cables.

To meet the new demand due to global technological developments in the automotive industry, which include all-electrical cars and subsequent needed infrastructure, Setic is leading the field with new development which has improved its already high-quality rotating machines. Enhanced high-speed double twist bunchers, single twist take-up with backtwist payoffs and various complete stranders solutions are perfectly adapted for the production of EV charging, batteries and data cables for this industry.

Thanks to its one step or two steps solutions, Setic perfectly replies to needs for 5G, IIOT, Robot and strong growth in the global LAN market. The needs of new cables for 5G, IOT, robots, and strong growth in the global LAN market are perfectly met by Setic's one-step or two-step solutions. Their large double twist range has been expanded to 2,600mm to produce 400mm/500mm Alu wires for low and medium voltage cables, with 61 wires compacted. This new development allows our partners to boost their productivity and reduce their operating costs. The portfolio of products gives the wire and cables industry the ability to select different state-of-the-art and advanced twinning and cabling solutions for producing a wide range of cables. Each solution being perfectly adapted to each of Setic's partners. The result is tailor-made solutions and new concepts to meet the Customers’ needs such as special high speed lines for battery cable, new high speed lines for special, control and instrumentation cables. Least but not last, Setic strives to meet the objectives of our partners in terms of social responsibility and decarbonization through the development and improvement of our organization, methods, and machines.

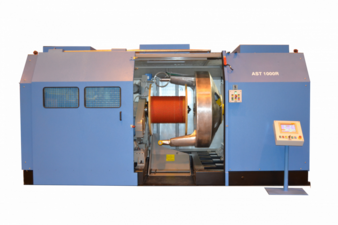

Products Showcase: One complete high speed 630 mm pairing line/quadding line composed of : Modernized design single bow Backtwist pay-off and Double twist machine for Data, Automotive and LAN Cables, presenting our Solutions for Industry 4.0. 1,000mm High speed Single twist assembling machine (AST1000R) illustrating their solutions versatility (LAN, control, instrumentation, data, EV charging and battery… cable) and flexibility (laying-up, stranding, wire armouring process). Pourtier produces heavy-duty rotating machines (rigid and planetary stranders, single twist cablers, drum twisters) to produce all types of power cables: overhead, Low, power cable up to High Voltage and Extra-high Voltage and submarine cables. Pourtier is the top choice when it comes to producing rigid and planetary stranders, single twist cablers, and drum twisters for all types of energy cables. Including overhead, low voltage up to high and extra high voltage as well as submarine cables. Pourtier connects its customers to all energy sources. Demand for clean energy including improved infrastructures has been on the rise in the past few years, resulting in new market challenges. Pourtier has the most advanced solutions to meet these challenges for sustainable clean energy and infrastructure. Pourtier being worldwide recognized for its engineering and manufacturing machines proposes heavy-duty stranders, cablers, screening and armouring lines. Its high efficiency revolutionary multiwire concentric stranding line is also widely used to boost the productivity for low and medium energy cables.

All of these machines are designed and manufactured with the highest standards in design and manufacturing to produce all types of high-voltage and extra-high-voltage power cables. From overhead cable (including ACCC , ACSS-TW and ACSR-TW) to submarine or land cables AC type (using high quality Milliken conductor) or DC type (using large round compacted conductor or profiled “Keystone” wires). Pourtier continue to expand its wide range of offering with higher number of wires up to 156 for rigid stranders together with pulling capstan up to 80 tons, and XL Drum Twisters up to 55 tons. Pourtier's long-term expertise and experience makes it an ideal strategic partner for projects of any size and complexity. Least but not last, Pourtier strives to meet the objectives of our partners in terms of social responsibility and decarbonization through the development and improvement of our organization, methods, and machines. Products Showcase : Digital immersion in a world of Bigger DC cables (Rigid stranders 127/156/171 wires, up to 5,000mm²) and Longer AC cables (opened cradle drum twister 55T)

C2S Customer Services department is the ideal partner to maintain machines productivity and enhance products quality. Rich of a long and successful experience, the C2S-Services division has an overall efficiency booster to maintain wire and cable production lines productivity and products quality, whatever the brand of the equipment. C2S is being assigned spare parts, upgrades and maintenance projects, as well as transfer and restart operations of complete lines. Upgrades are a sustainable approach. By extending the life of existing machines, customers reduce their environmental impact by minimizing the need of new equipment. C2S solutions are a way to save Energy and “Go Green”. C2S is involved in smart factories in their Industry 4.0 processes.

Bow Technology sells customized bows for all sizes and all brands of double twist equipment. Bow Technology is the answer to cable makers concerned by quality and long-life reliable bows for all brands of double twist machines from 560mm to 2,000mm. With a comprehensive range of 650+ all sizes designs the division offers a global service from conception to production. The patented GreenBow2 is a closed-bow model ensuring important energy savings (up to 30%) on high-speed double twist bunchers (560mm to 800mm). It’s time now to take your part of environmental questions towards a positive climate change, also in your industrial and professional life. The team is ready to discuss any model matching the customer’s production needs.

wire 2024, hall 10 booth F 59

Setic, Pourtier, C2S, Bow Technology

126, rue de Matel

42300 Roanne, France

Tel.: +33 4 77232555

setic@setic.info

www.setic-pourtier.com