09/04/2024 – Enhancing simplicity to deal with complexity

Micro springs

Coiling extra fine wire is a challenging task in the wire industry, as precision is paramount when dealing with diameters below a tenth of a millimeter. Imperfections are magnified when working with such thin wires.

Micro springs, a niche in the wire industry, have specific requirements to be determined every time during machine setup, as each spring and coil has its unique characteristics. Micro springs have a wide range of applications in medical, aerospace, microelectronics, and micromechanics fields. For instance, they are extensively used in precision micro springs for watches and electrical microcontacts.

However, working with such high levels of precision requires a great deal of attention to detail. Nothing can be overlooked. Before attempting to coil the wire, it is essential to inspect it for any abnormalities and ensure it is clean. Each stage of the process must be thoroughly verified as each presents its challenges, and finding a comprehensive solution to address them all seamlessly is no easy feat.

First and foremost, the structural condition of the wire plays a crucial role in the coiling process. Proper lubrication of all mechanical components of the machine is necessary, but the wire must remain clean with no oil leakage. Another challenge is maintaining the straightness and consistency of the coiling process for a tiny spring with almost no body. Coiling wire with such small dimensions can amplify problems tenfold, and those who work with it know the implications.

Customers should also consider the importance of tools and their preparation. Setting up a micro spring requires extreme precision since each component must be meticulously prepared and positioned. Then, it needs to be adjusted in the most accurate and effortless manner possible, considering the tiny dimensions and tolerances involved. Being able to prepare coiling tools easily is a crucial advantage when it comes to producing micro springs. If you examine tool grinding machines, Simplex Rapid’s “AFC 0” stands out from other grinders in terms of efficiency and user-friendliness. This machine enables even untrained tool grinding operators to prepare even the most complex tools with high levels of precision and repeatability in a very short time like no other grinder can.

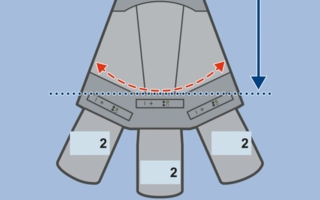

Last but not least, after completing the coiling, it is imperative not to overlook the sorting process. Adequately checking the produced springs, especially when dealing with micro springs and micrometric tolerances, is crucial to keep this critical process under control. Our electronic sorting chutes C equipped with sensors are designed to guarantee a 100% success rate. This can make all the difference between a good and an excellent production batch.

Simplex Rapid has conducted extensive research to simplify the delicate coiling process of micro springs, making it easier for operators to perform this complex task. Their goal has always been to manufacture machines that make the production of springs as user-friendly as possible while maintaining high-quality standards. When working with a Simplex Rapid machine, customers can be confident that they are working with the best. Simple solutions are the key to achieving this goal: after all, "less is more," and the company is proud to continue this tradition since 1948.

wire 2024, hall 16 booth G 18

Simplex Rapid Srl

Via Lombardia 13

20098, San Giuliano Milanese (MI)/Italy

Contact person is Vittoria Boschiero

Tel.: +39 02 98281751

info@simplexrapid.it

www.simplexrapid.it