28/03/2024 – Production of special screws

Larger diameters, two metals

Aachener Maschinenbau GmbH (Amba) will be showing two new “All-in-One” machines at “wire 2024”. The “BM 12” machine is the first screwmaking machine able to produce up to 70 screws per minute from Ø18mm - wire. “BM-BiMetal”, the second machine shown, is a further new addition to Amba’s “All-in-One” range. This machine can produce up to 100 bimetal screws per minute in an automatic mode.

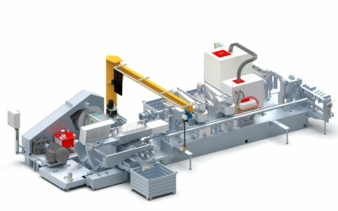

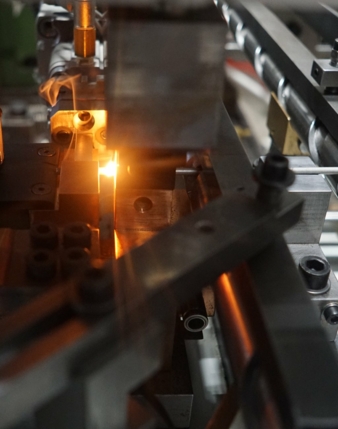

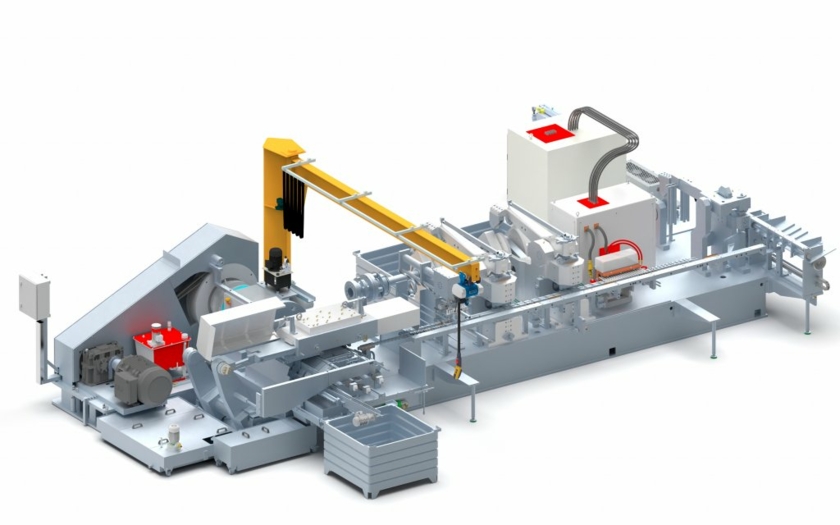

In the “All-in-One” screwmaking machines all process steps from wire pay-off, straightening and blank cutting, screw head upsetting up to and including thread rolling are performed within one single machine. © Aachener Maschinenbau

The new “BM 12” is the first screwmaking machine able to produce up to 70 screws per minute from 18-mm-dia wire. © Aachener Maschinenbau