28/03/2024 – Production of special screws

Larger diameters, two metals

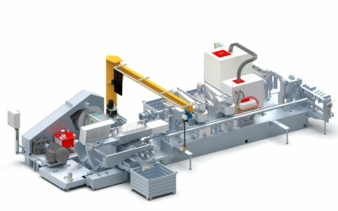

Aachener Maschinenbau GmbH (Amba) will be showing two new “All-in-One” machines at “wire 2024”. The “BM 12” machine is the first screwmaking machine able to produce up to 70 screws per minute from Ø18mm - wire. “BM-BiMetal”, the second machine shown, is a further new addition to Amba’s “All-in-One” range. This machine can produce up to 100 bimetal screws per minute in an automatic mode.

With the new “BM 12” screwmaking machine, Amba has increased the product range covered by its “All-in-One” machines to wire gages of up to Ø 18mm. The new machine forms wire gages of up to 12mm conventionally by cold-working. Its new feature is the integrated hot-forming capability for larger diameters: In the case of 12mm to 18mm gage wire, the material is inductively heated within the machine before upsetting. The blanks can be preheated to temperatures of up to 1,200°C. The machine is designed for production rates of between 50 and 70 items per minute.

The first machine of the new series will be used to produce up to 600-mm-long screws with thread diameters of 19mm or more directly from the coil. It will be installed at a US customer where it will replace two existing production lines consisting of several individual machines that require manual feeding. Here, the “All-in-One” principle will provide a marked boost in productivity as it performs all process steps from wire pay-off, straightening and blank cutting, screw head upsetting up to and including thread rolling within one single machine. Additionally, the new Amba machine will use much less space than the current equipment.

Machines for bimetal screw production

The new “BM-BiMetal” – which is also an “All-in-One” machine – can produce up to 100 self-drilling bimetal screws per minute fully automatically. These special screws are used in the construction industry for fastening profiled sheet metal roofing and façade cladding and in the energy industry for mounting solar panels, for example. The drill point of the screw is made from hardened carbon steel, the shank from stainless steel. These screws do not need a pilot hole. Therefore, they can be applied without extra pre-drilling.

So far, bimetal screws used to be produced on several separate machines, allowing only partial automation. Now, thanks to the Amba All-in-One approach, all process steps – from material feeding, forming of the screw head, weld joining of the carbon steel drill point to the stainless steel blank and thread rolling, up to the punching and heat-treatment of the drill bit – can be performed within one single machine.

wire 2024, hall 16 booth H 58

Aachener Maschinenbau GmbH

Werner-von-Siemens-Strasse 17-19

52477 Alsdorf/Germany

Contact person is Lars Henning

Tel.: +49 2404 551289-38

henning@amba.de

www.amba.de

About Amba

Aachener Maschinenbau GmbH – generally referred to as “Amba” – was founded in 1908, at a time when Aachen was worldwide famous for its high-quality needle production. Since then, the company has evolved into an internationally renowned manufacturer of machinery used to make cold-formed metal components. Today, Amba specialises in equipment for the production of long and slender components with varying cross-sections, such as screws between 60mm and 2,500mm long, and tubes and spokes. The Amba All-in-One design has made the company the world’s only supplier of machinery that can perform all steps needed to manufacture long and complex components continuously on just one machine. All process steps from feeding the input stock – wire rod or tube blanks – up to the finished, packaged product are handled by just one machine. This is unique in the industry. At its headquarters in Alsdorf near Aachen, Amba employs 80 people in its development and design departments, in the workshops and in after-sales.