04/07/2023 – “MASSdiscover” a pioneering solution

Instantaneous mass flow control for rolling mills

It is a new device that can measure mass flow in real time and calculate the equivalent cross-section or diameter.

“MASSdiscover” uses a technology that allows measurements with the highest precision to take decisions about the process control. It’s been used and tested in several rolling mills with harsh conditions and the results are fantastic.

Rolling mills for long metal products production starts with a billet that is passed through several rolls to get the desired final size and cross-section product.

The metal processing industry's high standards in terms of dimensional accuracy and product quality, added to the lack of control over production parameters often leads mills to deliver extra tons of steel, as it is difficult to delimiter quantity with high precision. Thus, rolling mills manufacturers suffer money losses. “MASSdiscover” goes beyond limits for fine tuning size adjustments on Long Product Rolling Mill Technology for metals.

Mass flow measurement is essential to control production parameters and avoid accidents. To date, expensive systems have been used for production optimisation, usually based on laser measurement, vision or other image analysis systems even electromagnetic technology. All these gauges have limitations, as they are not designed to control different points in the rolling mill, but only one point in the production process. Isend has found a highly reliable solution based on Eddy Currents, completely modular and conceived to fit the needs of each production line at a very competitive price. Mass Discover is based on the already well-known Eddy Current Technology for Long Product Rolling giving an electromagnetic signal depending on the fill factor produced in the probe.

How can “MASSdiscover” help customers?

“MASSdiscover” helps companies to adjust tolerances Product consistency. Allowing customers to:

– achieve a mini tolerance for longer product for reinforced steel

– achieve a mini variation on tolerances to ensure high performance post-treatment for fine drawing, cold heading, final product tensile consistency

In addition, when the size and speed of the material does not match the parameters of the rollers, accidents can occur. An example are the cobbles. This is why Isend goes further. The system not only helps to adjust the tolerances but also helps to ensure a good configuration of the production processes

– tension adjustments between stands

– size variation / wearing of roller grooves

– electric power consumption on each stand or group of stands

The control of these aspects entails enormous advantages for the rolling mill, which in summary will be reflected as follows:

– reduces line wear

– reduces accidents

– high ROI with saving on process time, product, control, maintenance cost

– higher reliability with well-known technology with less maintenance

– real-time analysis (during production)

– improve production environmental impact

– highest accuracy and performance

About the solution

MASSdiscover does not need to be in contact with the product to perform the analysis and its output is not compromised by dirt, powder, steam, water, or other kind of pollution in the environment. The mechanical design is one of the main strong points of the MASSdiscover system. Giving it a high robustness, has no moving parts and requires a little and easy maintenance.

– Isend’s eddy current technology

– higher frequency measurement

– easy integration with existing data base

– low maintenance

– internal Cooling System

– quick probe change (reducing downtime)

– special materials to support harsh conditions, such as speed and temperature of hot rolling mills

Installation where and how?

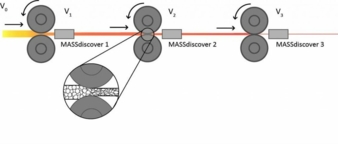

Due to low cost of ownership and the fact that MASSdiscover is a modular system, it can be placed at different checkpoints on the mill. In this way, the most critical aspects of production can be monitored under each customer preferences, offering an unknown level of production control. The control points can actually be installed from any place from intermediate mill to final stand.

– post intermediate mill

– pre-finishing stands

– finishing mill

– sizing mill

Isend

Ingeniería y Sistemas de Ensayos No Destructivos

P.T. de Boecillo. C/ Luis Proust 10

47151 Boecillo (Valladolid) Spain

Tel.: +34 983 132-307

contact@isend.es

www.isend.es