05/04/2024 – Surface treatment

“Helicord” technology for surface processing of wire and cable

At the 2024 “wire Düsseldorf” Boockmann Engineering will present their “Helicord” technology for surface processing of wire and cable, such as welding wire finishing or removal of misprints from cable, their “Helilub” technology for precision solvent-free lubrication of magnet wire, and their “Labtech” range of products for production-related analysis and measuring technology.

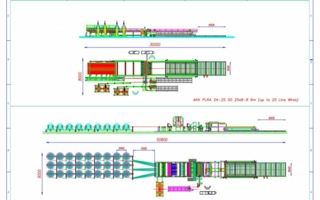

The “Helicord” and “Helilub” principle is based on friction between a fast-moving wire and a textile cord or yarn wound around a wire, strand or insulated cable multiple times, moving rather slowly under push-pullcontrolled conditions, creating a multiple 360° contact between the constantly renewed cleaning cord and wire.

Friction power on the wire increases linearly with the wire speed. This means the friction energy per wire surface unit and thus also efficiency is independent of the wire speed: “Helicord” can be run at drawing speeds.

The use of small amounts of liquids, such as water-based tensides, organic solvents, oil or a variety of dispersions, may be desirable or even required for both cleaning and coating processes, depending on the application in question.

For the welding wire industry, a variety of welding wire finishing cords is available, combining the superior properties of solid finishing materials with the high precision of “Helicord” coating. Other applications include, but are not limited to, cleaning insulated cable, applying primers or dispersions such as water- or solvent-based PTFE dispersions to bare wire or insulated cable, or even removing inkjet misprints from cable.

“Helicord” machines come in different shapes and sizes, suitable for anything from merely wiping off losely adhering dust and metal particles, right up to a two-step process for abrasive grinding and finishing. Product diameters range from fine wire to cables of up to 18mm.

Established in 1982, Boockmann Engineering has over 35 years of experience in bringing together utmost precision and environmental protection standards while providing customer-specific solutions that meet the highest quality requirements. Since then Boockmann Engineering has gathered invaluable knowledge in the wire and cable industry, and widened their scope of products and services. Focusing on delivering solutions rather than products and providing premium after-sales service and access to their wide knowledge base, they aim at 100% performance while keeping the “ecological footprint” as small as possible.

wire 2024, hall 9 booth C 34

Boockmann Engineering GmbH

Eckartspfad 6, 97708 Bad Bocklet/Germany

Contact person is Alyssa Balling

Tel.: +49 9708 7046-0

alyssa.balling@helicord.de

www.boockmann.com