13/11/2025 – Kurre develops next-generation fibre bundle machine

Fiber bundling system

The production of fiber optic cables comes with its own set of rules and challenges. Especially when manufacturing long lengths with many individual fibers, the process is particularly demanding. To produce high-quality fiber optic cables efficiently and gently, Kurre Systems relies on pre-bundling the fibers using a state-of-the-art fibre bundle machine.

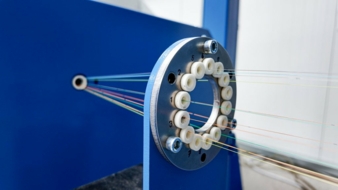

The binder yarn spinner, operating at up to 3,000rpm, is the centerpiece of the fiber bundling system. © Kurre Systems