30/03/2023 – Sustainability, effectiveness and flexibility

Everything starts from a spark

With the motto “Everything starts from a spark. Since 1923, the solution provider for your welding task”, Ideal-Werk can celebrate its 100th anniversary this year. Innovative, cosmopolitan and sustainable, the entire IDEAL family presents itself and with it its latest and most exciting topics.

Sustainability, effectiveness and flexibility – The implementation of the concept takes place in the machine type “CSR”. The “CSR” is a modular NC welding machine for welding products of one fixture placed on a rotary table with two machining sides. Effective multiple assignment of fixtures in the freely programmable working area is possible to increase efficiency. It is noteworthy that products can be both two-dimensional and three-dimensional in design.

New welding concept

The machine concept is based on the new welding concept – sustainability – without using the compressed air provided by the customer. The compressed air is used exclusively for static drives in the rotary table area. The welding units, which consist of an upper and a lower NC device, are individually controlled via the machine control. Compact customer-specific applications often result in multiple placement of NC welding units on the upper and lower consoles.

The highest degree of flexibility is achieved by the individual use of the NC units. In addition, there are no interfering edges that arise in programming due to fixture construction. Only the NC units in use are in the fixture construction for welding. It is worth mentioning that different welding tasks can be performed within one production run. A speed advantage of approx. 15% is also guaranteed by this use of the components. Furthermore, the storage of pneumatics as consumption is reduced to approx. 80% and leakages in the systems are a thing of the past. The effectiveness in terms of sustainability was proven in cooperation with the Hamm-Lippstadt University.

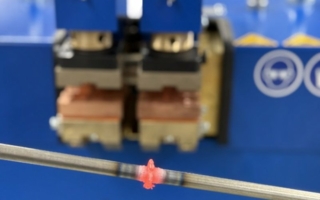

Double-pressure welding machine

The double-press welding process is mainly used in wire drawing plants, stretching and drawing lines. With the “DD0 104” double-press welding machine, as well as the “STS 020” from Ideal-Werk, the heat-affected material made of iron or non-ferrous metal is almost completely forced out of the welding zone after the welding process. This improves the mechanical properties, as well as the design of the weld.

With the “STS” or “DD0” type series, high welding quality and enormous strength can be achieved. At the same time, the machine is characterized by high reproducibility of welding parameters. The ideal solution for customer’s application in coil vertical haul-offs of stretching lines and drawing lines.

Top 100 Innovator

Ideal-Werk has successfully participated in the innovation competition “Top 100”. As a very innovative medium-sized family business, they have convinced with their innovative qualities and were therefore awarded the “Top 100” seal 2023. Especially in view of their 100th anniversary, they are very pleased to be counted among the "Top 100" innovators in Germany.

Ideal-Werk C. + E. Jungeblodt GmbH+Co. KG

Bunsenstrasse 1, 59557 Lippstadt, Germany

Contact person is Lara Reen

Tel.: +49 2941 206-219

Reen@ideal-werk.com

www.ideal-werk.com