06/12/2022 – New era for maintaining constant tension in stranding processes

Control of wire tension

The monitoring or control of wire tension is of vital importance for manufacturers, and is especially true when it comes to offering the consistently high product quality demanded by their customers. The aim is to always be able to offer the best products at competitive prices, and this requires wire processing machinery operating at peak performance.

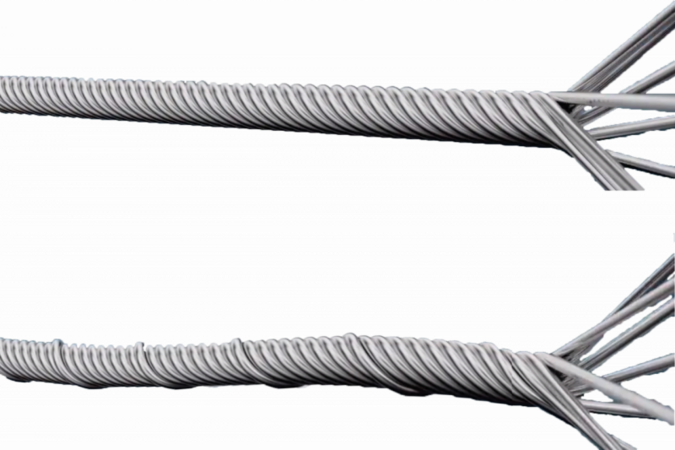

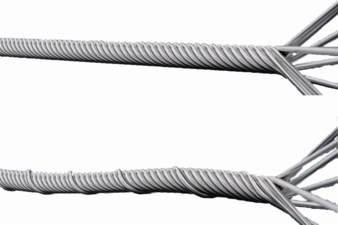

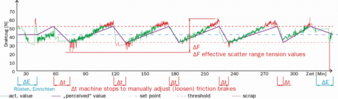

Top: equal tension on all strands Bottom: Typical fault pattern with widely differing tension values per strand. © FMS

Top: equal tension on all strands Bottom: Typical fault pattern with widely differing tension values per strand. © FMS

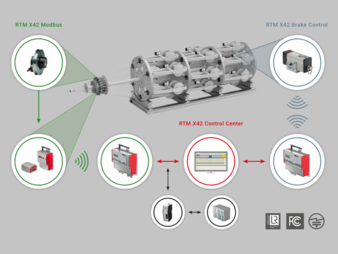

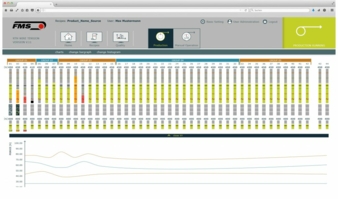

Without tension monitoring and with manual adjustment of the friction brakes: ?t Downtime up to 25% ?F Large deviation of the measured tension strength © FMS

Automatic, closed loop tension control with uninterrupted operation: NO ?t - Up to 25% more throughput Smaller ?F - Increased product quality (up to 45% reduced deviation). © FMS

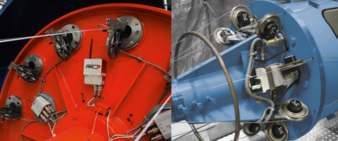

Force sensors installed close to the stranding point of the machine measure the tension of up to 42 individual wires or strands. © FMS