02/05/2023 – Sustainable cable materials

Colouring recycled PVC

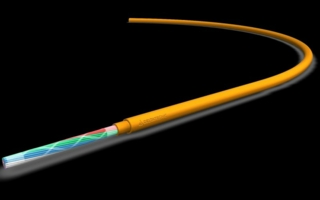

Delta Tecnic transforms recycled PVC products with its line of colour masterbatches. The company helps processors of recycled plastic to improve the colour of the products made from it and make them more attractive to the market. Whether in black, white or any other specific colour, PVC gets a second life that contributes to the preservation of the environment.

The latest market study on polyvinyl chloride by the consultancy Ceresana forecasts that demand for PVC will continue to grow and reach about 57.7 million tonnes worldwide by 2031. In Europe, more than 810,000 tonnes per year are already recycled, which is more than a quarter of all PVC waste. This means that the recycling rate of PVC is better than that of other plastics.In a world where sustainability and economy are crucial, Delta Tecnic offers innovative solutions to give plastic products that have reached the end of their useful life a second chance. With its line of colour masterbatches for recycled PVC, the company helps improve the colour of recycled products, making them more attractive to the market and contributing to the conservation of the environment.

The useful life of PVC in particular plays a fundamental role in the market. Manufacturers are constantly looking for ways to create durable and reusable products, using the right raw materials for this purpose. When a product ultimately reaches the end of its useful life, the aim is to give it a second chance through recycling.

Thermoplastics are generally recyclable, so the common use of the term “recycled” describes products that have been transformed and reintroduced to the market at the end of their initial useful life. Delta Tecnic is specialized in offering solutions through its colour masterbatches to help improve the final colour of recycled PVC products, whether in black, white or any other specific colour, giving the plastic a second life.

Three ways to recover the colour of recycled PVC

1) Plastic that is made up of different colours is usually transformed into black using carbon black concentrates.

2) For white PVC which is to be reintroduced in the same colour, it is important to note that due to thermal stress, the recycled product tends to yellow. For this reason, Delta Tecnic offers a range of white masterbatches containing titanium dioxide, in many cases custom made, that help to improve the final colour.

3) When a manufacturer wants to create parts in a specific colour, Delta Tecnic recommends separating the residual products by colour and making a specific masterbatch for each colour, thus improving the final colour of each part.

The company has been helping the PVC industry to incorporate colour in all its applications for more than 40 years. Waste managers purchase end-of-life products with the aim of reforming them as plastic. These recyclers shape the products into pellets with an extruder and the recycled compound is then sold to plastic parts transformers. In this way, Delta Tecnic supplies its special masterbatches to be introduced during the PVC recycling process to improve the quality of the final component.

The recycling rate of PVC is one of the highest

The latest market study on polyvinyl chloride by the consultancy Ceresana forecasts that demand for PVC will continue to grow and reach about 57.7 million tonnes worldwide by 2031. In Europe, more than 810,000 tonnes per year are already recycled, which is more than a quarter of all PVC waste. This means that the recycling rate of PVC is better compared other plastics.

Interwire 2023, booth 1639

Delta Tecnic

Pol. Ind. Molí de les Planes

Carrer Rec Molí de les Planes, s/n

08470 Sant Celoni, Barcelona, Sain

Tel.: +34 938 674 284

deltatec@deltatecnic.com

www.deltatecnic.com

About Delta Tecnic

Delta Tecnic was founded in 1982 to commercialize raw materials in the plastic, cable, ink, paint, and cosmetic industries with the distribution of leading brands worldwide. With a total of 20,000m² in facilities, three production plants, two of them located in Barcelona (Spain) and one of them in Querétaro (Mexico), Delta Tecnic has grown to position itself as a company leader among Trading companies in Spain, as well as one of the main producers of Masterbatch for the cable and PVC industries globally. Among the three divisions of Delta Tecnic, DeltaColor Masterbatch stands out, whose production capacity reaches 18,000t/y. In addition, the division has more than 11,000 developments and 22 production lines. On the other hand, the Delta Trading Pigments and Plastics divisions distribute in leading firms such as Eckart, Cabot, Baerlocher, Cinic, or Aralon. With 3% of global turnover dedicated to R&D, the company is focused on technological innovation and quality of service, providing deep knowledge of the market and formulations, always optimizing customer processes to become a technology partner focused on product development and innovation. At present, it already exports to more than 60 countries with an export volume of 80%, becoming one of the main players in the market.