27/06/2022 – Cutting

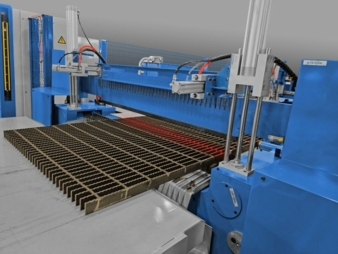

Automated grating shear

Traditional methods of cutting gratings such as the use of band saws, cold saws or manually using gas torches are a thing of the past. Clifford's new grating shear is designed to automate the cutting process allowing for fast cutting of programmable cut lengths, giving greater efficiency and flexibility than traditional methods.

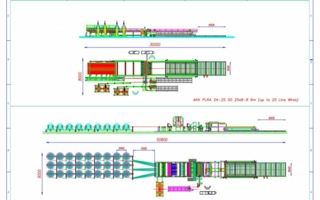

The grating shear can be integrated into any standard grating welder producing either cut-to-length or off-coil gratings or can be used as a stand-alone unit.·The traditional approach to cutting grating is using band saws or cold saws. Using shear technology, the following advantages are realised:

– High consumable costs for saws: The shear tooling lasts hundreds of thousands of shears if well maintained.

– Reduced downtime required for tooling changes: Traditional cold saw and band saw tooling has to be sharpened or replaced regularly resulting in downtime during tooling replacement. Shear tooling lasts hundreds of times longer than traditional tooling reducing inefficient downtime during tooling changes.

– Noise factor: Shearing limits the continuous noise associated with cold saws and band saws.

– Speed: Cold saws and particularly bandsaws take significant time to cut through the grating. Productivity is significantly increased using shear technology.

– Overall running cost: Due to increased productivity less manpower, machine space and utility costs are required using shear technology. Reduced consumable costs contribute to lower overall running costs as well as downtime associated with changing saw blades.

How it works

Standard or stainless-steel grating is loaded onto the input table, where side clamps and linebar grippers keep the grating in position. The grating is then fed into the portal with the servo controlled grippers. The shear has an automatic height adjustment and axis rotation for automatic angled cuts. Cut grating is then pushed onto the output roller table where the gratings can be stacked on pallets and stored.

Features

– Shear cuts can be performed in numerous different ways on the panel

– Grating panel tail and leading-edge trimming

– Variable leading-edge and tail length overhangs

– Multiple cuts in one cross wire pitch

– Slug cutting

– Fishbone cutting

– Different cut lengths within one panel

– A slug clearing device ensures that no slugs are left in the shear tooling potentially causing blockage or damage to the tooling.

– A slug Shute to remove cut pieces

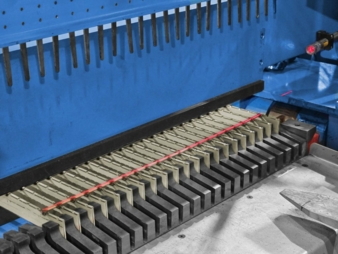

– A panel in-position sensor (green laser below), to confirm that the blades are fully engaged with the grating panel, prior to the cut

– A laser is mounted on the shear blade, enabling the operator to align the blades with the cross-wire, if the cross-wire is not perpendicular to the line bars

– The shear base has an adjustable pivot point in the centre of the base, enabling the operator to set the cut angle prior to the cut

Customers can have their grating lined up on the input table and watch as the shear cuts their grating at high speeds, or they can match the speed of their grating welder.

Clifford's shear blades have been designed to be symmetrically reversible and reusable. So the blades can be rotated and then sharpened, saving time and money.

Two light curtains, an auto-locking gate, and a safety fence on the perimeter and all machine controls in safe areas ensure the operator remains out of harm’s way at all times.

Clifford Machines+Technology PTY LTD

24 White Road, 3201, Pietermaritzburg, South Africa

Contact person is Iain Ambler

Tel.: +27 333 553410

ambleri@cliffeng.com

www.cliffeng.com