28/03/2022 – From the wire coil straight to 420-mm-long full-thread screws

All-in-one screw making machine caters to trend

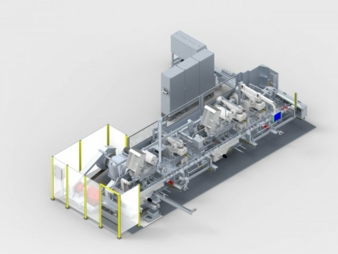

At “wire 2022”, Amba is going to introduce its new all-in-one machine for the production of 10-mm-diameter full-thread screws in lengths of up to 420mm.

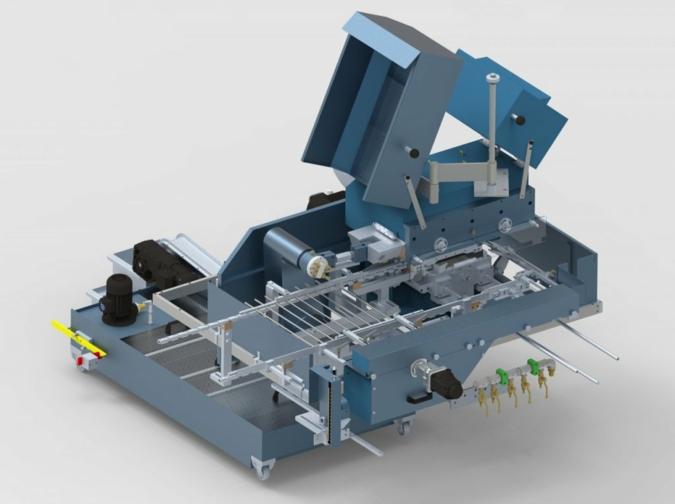

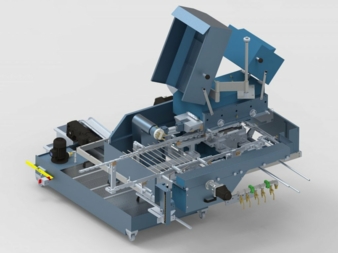

The core unit of the all-in-one machine is one of the two integrated threading stations. © Aachener Maschinenbau

The new all-in-one machine developed by Amba is the first in the world to produce up to 420-mm-long full-thread screws in one continuous process directly from the wire coil. © Aachener Maschinenbau

The core unit of the all-in-one machine is one of the two integrated threading stations. © Aachener Maschinenbau

There is a growing demand for full-thread screws of 420 mm length in wood construction. © Aachener Maschinenbau