22/05/2023 – Optical Scanning System

Accurate and easy way to perform Brinell Testing

Ametek Newage Testing Instruments, an established manufacturer and worldwide supplier of hardness testers and accessories, announces the launch of its improved Brinell Optical Scanning System, „B.O.S.S.“

Brinell testing is a widely used method for measuring the hardness of metals. There are several reasons why this method is so popular, including that Brinell testing can be used for all types of metals and that it offers a very accurate and simple testing method.

The manual reading is quite easy and straightforward, but here you come across what is also the one disadvantage of the Brinell method. The manual reading via microscope has a high risk of human error and requires training and concentration to achieve accurate results. Since the formula for the Brinell Hardness Number (BHN) calculation highly depends on the indent impression reading, these readings require high accuracy.

That is why Ametek Newage developed the „B.O.S.S.“ system which virtually eliminates operator influence on the test results. The system represents the most significant technological improvement to Brinell testing since the test was first introduced. It measures Brinell impressions faster, more accurately and more consistently than other solutions, and it improves quality control with advanced data acquisition and analysis capabilities.

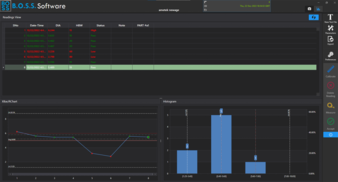

„B.O.S.S.“ uses a compact scanning head attached to a computer using a software to measure impression diameters in seconds and yields a measurement resolution of 0.01mm. The „B.O.S.S.“ software is used to set up the criteria for the reading and performs the necessary Brinell Hardness Number calculations to ASTM standards. The system even takes into account such anomalies as impression roundness and surface finish of samples.

In this latest launch, the software has been optimized with an even better user interface that is very intuitive in a familiar window-based environment and with faster and easier installation. The new configurable display shows the 10 most recent readings and features customizable measurement screens you can configure to tailor the software to your specific application. An updated demonstration mode allows for multiple impressions, creating an improved sales and training experience.

The new software version is available now and more information can be found at: www.hardnesstesters.com.

Ametek Newage Testing Instruments

8600 Somerset Drive

Largo, Florida 33773, USA

Tel.: +1 727 5386127

newage.orders@ametek.com

www.hardnesstesters.com

About Ametek Newage Testing Instruments

Ametek Newage Testing Instruments has manufactured and supplied hardness testing and microhardness testing equipment globally for more than 70 years. Among some of the proven product lines supplied by the company are Versitron, Indentron, MT-91 and HiLight. Newage Testing Instruments is a part of Ametek STC, a world leader in materials testing equipment, calibration instruments, and factory automation. Ametek, Inc. is a leading global provider of industrial technology solutions serving a diverse set of attractive niche markets with annual sales over $6.0 billion.