10/03/2020

Powerful technology for Non-Destructive Testing

Eddy currents are a powerful technology for Non-Destructive Testing (NDT) to check the surface quality of metallic long products. Most of existing applications are based in the use of differential or absolute coils and probes to find discontinuities due to flaws or any characteristic changes like conductivity or hardness.

There are many possibilities with hot and cold rolled long products. Eddy currents deliver a countless value when long bars are rolled, because they are not affected by the manufacturing variables, being resistant to many of them. Let us take a look at the Ø5.5 hot rolled wire rod. Eddy current coils are used to find surface defects when the bar reaches its end shape and dims. It’s usually placed after the finishing block. These coils work at high both temperature and speed, without any influence from steam, water or foreign matter (except incrustations or hairs that are considered rolling defects). On the other hand, vision systems are affected by the environment. This is the source of the solutions “Hot discover” and “Eddy eyes” family.

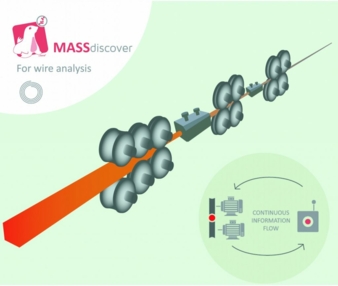

Isend has applied their technological knowledge in this production environment, developing a new coil generation that can be used at any point of the rolling mill to measure the instant mass and speed accurately. In addition, these measures can be used for the automatic rolls setting avoiding the different speed between rolls and material that produces defects and cobbles. This is solved through “Mass discover” family. Eddy technology is enormously reliable and easy to maintain, delivering an attractive cost. Other solutions, like laser or vision, are more expensive and environmentally dependent, being their application almost unfeasible.

Therefore, Eddy current applications cover not only traditional uses, like non-destructive surface testing but they measure also mass (section) and speed in any point of the rolling mill. And rolling mills can get a powerful map of defects including mass measures that add a big value to every high quality steel maker.

Isend, S.A.

wire/Tube 2020, hall 6 booth A 02

Tel.: +34 983 132-307

www.isend.es