05/08/2021 – Deep learning streamlines industrial image analysis for material inspections

Olympus “Stream” software’s AI

Olympus “Stream” image analysis software now leverages the power of artificial intelligence to bring next-generation image segmentation to industrial microscope inspections.

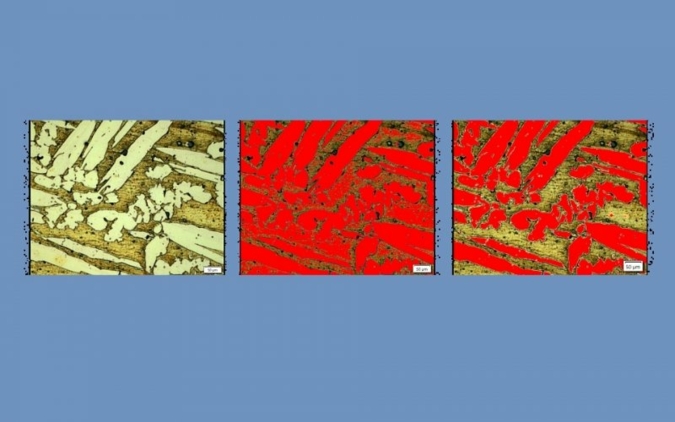

Multiphase analysis of composite materials is a typical industrial image analysis application using deep-learning technology. After deep-learning image segmentation with OLYMPUS Stream software version 2.5, different phases can be distinguished and detected accurately. Combined with the software’s Count and Measure solution, users can easily obtain repeatable and quantitative results. Left: Original image of etched copper. Middle: Image segmentation using conventional thresholding methods. Right: Deep-learning image segmentation. © Olympus

Multiphase analysis of composite materials is a typical industrial image analysis application using deep-learning technology. After deep-learning image segmentation with OLYMPUS Stream software version 2.5, different phases can be distinguished and detected accurately. Combined with the software’s Count and Measure solution, users can easily obtain repeatable and quantitative results. Left: Original image of etched copper. Middle: Image segmentation using conventional thresholding methods. Right: Deep-learning image segmentation. © Olympus