25/03/2019

Latest innovations in wire and cable production technology

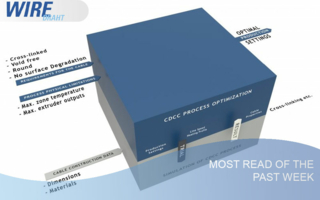

Maillefer and Davis-Standard at Interwire 2019 will showcase the next step in the digitalisation of manufacturing and introduce the "Smart Factory". With the virtual reality application, visitors can simulate different production parameters and set-ups applicable in Maillefer works.

While the full spectrum of their consultation products is now available at the company’s website, altogether ten new solutions will be shown at the Interwire booth. Maillefer Smart Factory combines a physical factory model with additional instrumentation and online diagnostics, enabling the prediction of abnormal process behaviours before critical quality issues take place. For example, with online curing control “OCC” you can manage your curing process in real time using exact process measurements. As a result, there are fewer scrap and cable failures.

For more complex production systems, Davis-Standard offers an advanced “EPIC III” process control solution with data acquisition. This Windows-based solution can be customised for any extrusion application. Advantages include a 23 inch wide monitor, a detailed graphic overview and custom report feature, historical trending, event log and data collection, multi-level security and network capability. In medium, high and extra high voltage cable production, Maillefer “Topography Scanner” controls customers extrusion quality continuously. They can find an optimal set of parameters and increase the productivity of their CV line.

For fibre optic cable producers, the Maillefer “Smart Buffering” concept sets totally new limits for line speeds. It analyses and understands the relations between the process data and the end-product properties and offers enhanced operator guidance. The concept could bring up to 400,000 US-Dollar in annual material savings. Rubber cable production gets its own innovation with Davis-Standard’s multipurpose cold feed rubber extruders. These extruders are technologically advanced, reliable and built for longevity for a wide range of rubber applications. Davis-Standard also offers the “DSREV” extruder in multiple configurations. This extruder design features a patented pneumatic roll feed system for uniform and consistent feed rate, electric heating and water-cooling for quicker response times, and feeds crew designs that maximise output and minimise scorch. Maillefer “Crosshead ECH 12/16 OF” offers excellent concentricity, high performance and exceptional user friendliness. Alignment stand “ALS 40” is the answer for misalignment issues in secondary coating. It ensures that all necessary components are always perfectly aligned, enabling a stable process and easy operation.

Maillefer Extrusion Oy

Interwire 2019, booth 823

Tel.: +358 44 0124003