10/05/2023 – Cold forming

Fully automatic cold-heading and hot-forging lines

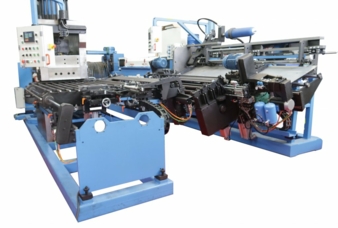

Videx’s hot forging machine turns into a complete line, starting from bars or coils.

The line will feed the bars, shear to length, chamfer and extrude the end, forge a head in a closed die without trimming, cool and thread. Videx forging machines are available in 100 to 500 metric tons. These lines will automatically and efficiently manufacture long, headed fasteners without trimming. Videx’s open-die Cold Headers are now also offered as automatic lines, starting from coils or bars. The lines start with a wire straighten, cut, and chamfer machine. The cut-to-length parts are fed into a multi-operation transfer machine which will turn, chamfer, face the ends, stamp, drill and even insert Aluminum balls for Weld-Studs. Once all these operations are complete, the parts will be transferred to a dual-station cold-header, where they will be headed on the opposite side. These lines are an efficient solution for production of cold-headed long bolts, weld-studs, etc.

Details:

Thread range: M-20 to M-48 and up

Part length: 250mm to 1,000mm.

Production: 4 to 6 parts per minute.

Videx Machine Engineering Ltd.

20 Shabazi St., Yahud 5623107, Israel

Contact person is Yair Wiesenfeld

Tel.: +972 3 5364801

videx@videx.co.il

www.videx-machine.com