23/07/2025 – Final acceptance certificate

Primetals elevates Outokumpu’s meltshop and caster performance with automation upgrade

Primetals Technologies has received the final acceptance certificate (FAC) from Outokumpu Stainless USA for the successful upgrade of process optimization systems at its Calvert, Alabama facility.

The project included a comprehensive Level 2 automation system upgrade across the entire meltshop and casting areas. The new systems are provided under a 7-year subscription model that ensures state-of-the-art plant operations and continuous improvements through regular software updates.

Subscription Model

The subscription model transforms high one-time costs into manageable annual license fees, while ensuring compatibility with future software updates. Lawrence Bailey, Level 2 Network Administrator at Outokumpu in Calvert, emphasizes the importance of this model: “It is important for us to continually improve the quality and flexibility of our Level 2 automation system. The software subscription for Primetals Technologies’ process optimization software helps us in this endeavor by keeping all systems up to date.”

Improving Performance

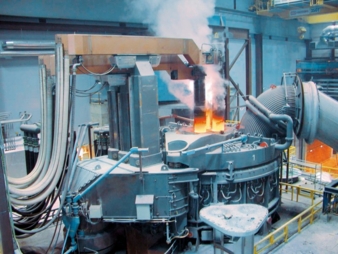

The upgraded systems – EAF Optimizer, AOD Optimizer, LTS Optimizer, CC Optimizer and Through-Process Quality Control (TPQC) CCM, and the Ladle Tracker – enable Outokumpu to take full advantage of the latest functionality and process models. This improves performance and resource efficiency and supports Outokumpu's commitment to sustainability by reducing energy consumption and maximizing resource utilization, all while enhancing the plant’s agility to adapt to changing market demands.

Long-term partnership

Outokumpu Stainless USA’s collaboration with Primetals Technologies dates back to 2012, when the meltshop and caster were first equipped with advanced process optimization systems. Since then, Primetals Technologies has provided continuous support through on-demand assistance, training and incremental software updates as part of ongoing service contracts.

“A subscription model is the only modern way to source automation software. We have come to recognize Primetals Technologies as a reliable partner in the development of modern automation systems. Going forward, we will be in constant contact and will be able to continuously develop our models as part of the software subscription,” says Lawrence Bailey.

About Outokumpu

Outokumpu is accelerating the green transition as a global leader in sustainable stainless steel. Outokumpu’s business is based on the circular economy: its products are made from 95 % recycled materials, which are then turned into fully recyclable stainless steel. This steel is utilized in various applications across society, including infrastructure, mobility, and household appliances. In the US, Outokumpu operates America’s most advanced stainless-steel mill in Calvert, Alabama. With its extensive range of products and industry-leading technical support and services, Outokumpu is the second largest producer of sustainable stainless steel in the United States. www.outokumpu.com

Key Facts:

Extensive Automation Upgrade at Outokumpu Stainless USA

Production units upgraded

EAF, AOD converter, ladle treatment station (LTS), continuous caster

Software applications

EAF Optimizer, AOD Optimizer, LTS Optimizer, CC Optimizer, TPQC CCM, Ladle Tracker

Subscription duration

7 years, with automatic annual extensions