26/10/2021 – Wafios accelerates the transformation of modern drives

Former “Südwerk” in Reutlingen becomes new “E-Mobility Campus”

The Wafios AG Supervisory Board unanimously approves the Executive Board’s proposal to establish the “Wafios E-Mobility Campus” on the premises of the former “Südwerk” in Reutlingen/Germany.

At the Supervisory Board meeting on Friday, October 15, 2021, a major milestone was set for the future direction of Wafios AG in Reutlingen, Germany. The Supervisory Board approved an investment of € 10 million to establish and build the Wafios Campus for Electro Mobility. The investment sum is distributed as follows: € 5 million for sample part and prototype production machinery, € 3 million for the modernization of buildings and € 2 million for infrastructure and workplace measures. The campus will comprise a total area of 1,800 m², additional space is available if needed.

Wafios' activities in the e-mobility sector will be pooled at the E-Mobility Campus. From the development of machines, to the customer center, to the production of prototypes and sample parts, to the commissioning of machines, all will be under one roof on the E-Mobility Campus.

Wafios’ historical factory hall will become a high-tech center of electro mobility. By taking this step, Wafios advances their developments and efforts in this field, which they started more than 5 years ago, and strengthens their commitment to technology of the future.

The company thus sends a clear signal and reaffirms its commitment to their headquarters in Reutlingen. Establishing and expanding the new technology center also requires new employees. The according job offers can be viewed online in the new applicant portal https://www.wafios.com/karriere/berufserfahrene/.

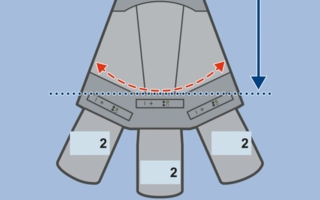

Wafios’ dedication to electro mobility began more than 5 years ago with the development of unique bending technologies for busbars and subsequently also for hairpins as a central module for the production of stators for electric motors. Sales in the prototype manufacturing sector alone have multiplied in the last three years. The development of a unique hairpin bending technology was the result of 128 years of expertise in wire processing technologies and more than 45 years of CNC technology know-how. What makes this technology so special is that the wire is not only a moving object that needs to be shaped but that the material is guided and processed so that defined and reproducible components are created. The newly developed Wafios “Speedformer” is software-controlled and can thus produce a wide variety of parts without the need to change tools. It achieves a cycle time of 1 to 1.3 seconds per part. This means nothing less than the leap from prototype production to series production. The response from customers to the new technology also speaks for itself and ranges from “very impressive” to “highly enthusiastic”.