20.03.25 – Research project

University of Paderborn: Research on process-flexible self-pierce riveting and clinching using standardized joining tools

Self-pierce riveting and clinching are established joining processes in car body construction. Although the joining tools are similar in both processes, individual tool geometries are currently used in production.

This article describes an approach to standardizing the joining tools and demonstrates its feasibility.

Self-pierce riveting has established itself in car body construction, particularly for joining mixed material components [1]. Compared to spot welding, it is characterized by the high load-bearing capacity of the joints produced [2]. Both aluminum materials and press-hardened steels can be joined using self-pierce riveting [3]. Clinching is preferably used for joining add-on parts such as hoods. The achievable joint load-bearing capacity is reduced compared to self-pierce riveting [2]. Aluminum materials and lower strength steels can be joined [4]. In this area, the range of materials that can be joined overlaps with self-pierce riveting. For this reason, efforts were made 20 years ago to standardize the joining tools, consisting of punch, blank holder and die, as well as the system technology of both processes [5]. In order to enable increased flexibility of the two joining processes, the research project “Process-flexible punch riveting clinching tools for mechanical joining” (IGF no.: 01IF22047N) aimed to develop process-flexible tool geometries for joining multiple different material thickness combinations. The research project was carried out by the Laboratory for Materials and Joining Technology (LWF) at Paderborn University and the Fraunhofer Institute for Machine Tools and Forming Technology (IWU). The design of the process-flexible tool sets was carried out with the aid of simulation-based sensitivity analyses. The geometry parameters of the joining tools, such as the diameter and depth of the dies, were varied for this purpose. By evaluating the results, it was possible to identify overlaps between the possible tool parameters. A more detailed description of the investigations can be found in [6].

Experimental proof of feasibility

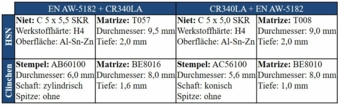

This article describes the feasibility of the approach using two material thickness combinations. A joining system of the type TOX TZ-VSN (TOX Pressotechnik GmbH & Co. KG) is used to carry out the joining tests. The system enables joining by means of self-pierce riveting and clinching through the use of different tool holders. A joining task involving the joining of the steel material CR340LA and the aluminum alloy EN AW-5182 was selected for the study described. Different joining directions result in two material thickness combinations and therefore different requirements for the two joining processes. Rivets and dies from Tucker (Stanley Engineered Fastening - Tucker GmbH) are used for self-pierce riveting. Tools from TOX (TOX Pressotechnik GmbH & Co. KG) are used for clinching. The selected rivets, dies and clinching tools are summarized in Figure 1.

The punch for self-pierce riveting has a diameter of 7.5 mm. The reference joints produced and the measured joint characteristics in the cross-section are shown in Figure 2.

Suitable geometries of the joining tools for both joints and processes were derived with the aid of numerical simulation. A BE8014 clinching die is used for both joints and both joining techniques. The diameter of the punch is 6.0 mm. The results of the experimental joining tests are shown in Figure 3.

It can be seen that the smaller punch diameter causes a small indentation on the rivet head. As the joining force remains unchanged with the same rivet, the load in the rivet head increases due to the smaller contact area between the punch and rivet. As the diameter of clinching punches is always smaller than the 7.5 mm diameter of the riveting punch, an optical impairment must be accepted when using standardized joining tools for self-pierce riveting. However, as the rivet head always represents a visual impairment of the sheet metal surface, this effect can be tolerated. An effect on the mechanical properties of the rivet and the joint is not to be expected, as the very slight deformation takes place in an area that is not relevant for the joint load-bearing capacity. The clinching tools are therefore also suitable for self-pierce riveting. The clinched joints fulfill all quality criteria. It can therefore be concluded that both material thickness combinations can be joined using self-pierce riveting and clinching with uniform joining tools.

Funding information

The results shown originate from the IGF research project 01IF22047N of the European Research Foundation for Sheet Metal Working (EFB), which was funded as part of the program for the promotion of industrial research (IGF) of the Federal Ministry of Economics and Climate Protection (BMWK) on the basis of a resolution of the German Bundestag.

https://mb.uni-paderborn.de/en/lwf

Literature

[1] Li, D.; Chrysanthou, I.; Patel, G.; Williams, G.: Self-piercing riveting - A review. International Journal of Advanced Manufacturing Technology 92 (2017) S. 1777-1824.

[2] Mori, K.; Abe, Y.: A review on mechanical joining of aluminium and high strength steel sheets by plastic deformation. International Journal of Lightweight Materials and Manufacture 1 (2018) S. 1-11.

[3] Information sheet DVS 3410, Semi-tubular self-pierce riveting – Overview (Merkblatt DVS 3410, Halbhohlstanznieten – Überblick), DVS Media: Düsseldorf, 2019.

[4] Information sheet DVS 3420: Clinching – Overview (Merkblatt DVS 3420: Clinchen – Überblick), DVS Media: Düsseldorf, 2021.

[5] Breckweg, A.; Wößner, J.: Device for joining panel-shaped components with variable joining technology (Vorrichtung zum Verbinden von plattenförmigen Bauteilen mit variabler Fügetechnik). Patent DE10332124B4, 2003.

6] Uhe, B.; Schützelt, F.; Drossel, W.-G.; Meschut, G.: Flexible self-pierce riveting and clinching with a single joining system using the same unified joining tools. Materials Research Proceedings 41 (2024) S. 1696-1704.