03/08/2019

Energy-efficient superconducting cable

The Karlsruhe Institute of Technology has developed a superconducting cable which - when cooled with nitrogen instead of helium - transports large quantities of electrical energy almost loss-free. It should be easy to manufacture. Industry is working on mass production processes.

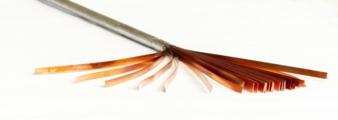

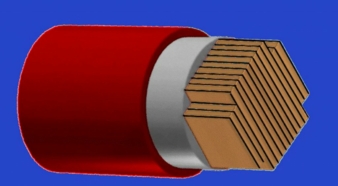

Superconductors transmit electrical current at low temperatures with almost no losses. This makes them attractive for a whole range of energy-saving technologies. However, this usually requires cooling with liquid helium to a temperature close to minus 269°C. This is the case, however, for example, with the use of a heat exchanger. A new cable from the Karlsruhe Institute of Technology (KIT) is already ready for use at minus 196°C. The new cable can be used for the first time in a wide range of applications. Nitrogen can be used for cooling. The superconductor Cross Conductor (HTS CroCo) transports large amounts of electrical energy, “This is due to the special material we process,” explain Walter Fietz and Michael Wolf from the Institute of Technical Physics at KIT. Rare-Earth Barium Copper Oxide (Rebco for short), whose superconducting property has been known since 1987, is used. However, this superconductor can only be produced in long lengths in the form of thin strips.

“We have now developed a method in which several Rebco bands are arranged crosswise. This creates a cable for very high currents,” says Fietz. The high current carrying capacity of the HTS CroCo saves space and weight compared to conventional cables made of copper or aluminum alloys. The manufacture of the cable is also efficient: several manufacturing steps are combined in a manufacturing process developed at KIT. “We are currently already achieving a production speed of one meter per minute in a demonstrator production facility,” reports Wolf. In a correspondingly scaled industrial production plant, cable lengths of several 100m and more would be conceivable, which would save costs. Since the superconducting layer – which conducts the current – in the finished cables is only a few thousandths of a millimeter thick, material costs are also kept within limits.

Industry is tinkering with manufacturing processes

“Mass production has so far been hampered by high costs for the production of Rebco tapes,” says Wolf. At the moment, however, the industry is developing processes to make them cheaper. The CroCo is suitable for the energy-saving generation of strong magnetic fields, but also for transporting large quantities of electrical energy. This would make it possible, for example, to integrate large wind farms or solar power plants into the power grid and make power highways leaner. If liquid hydrogen is used to cool the CroCo, chemical and electrical energy can even be transported together. “In principle, a CroCo can be used wherever little space is available but a lot of electrical energy needs to be transported,” says Fietz. It is therefore also conceivable that it could be used in ships and fully electric aircraft.

As “The Research University in the Helmholtz Association”, KIT creates and imparts knowledge for society and the environment. The aim is to make contributions in the fields of energy, mobility and information. To this end, 9,300 people work together on a broad disciplinary basis in the natural sciences, engineering, economics, the humanities and social sciences.

Karlsruhe Institute of Technology (KIT)

Institute for Technical Physics

Rintheimer Querallee 2

76131 Karlsruhe/Germany

Contact person is Mr. Walter Fietz

Tel.: +49 721 608-23501