20/01/2020

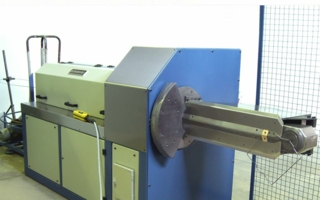

Wire multi-stand rolling mill “EFFE” series

Invimec is specialized in cold rolling mill and forming solutions. Winning tool of the company is the total modularity of the single and multi-stand rolling machines, based on single-drive technology. Specific and niche problems can be solved thanks to the long experience and know-how achieved.

The Single-drive system consists in the creation of motorized and independent stands, which guarantees a total flexibility for different materials and working conditions. The sophisticated electronic regulation system allows to successfully roll even critical materials thanks to accurate tension control. The application field covers every metallic material which needs cold deformation, for example precious material, like gold, silver and platinum, welding and brazing alloys, hard-to-draw materials, Nb, Zr, Ta, Hf based alloys. More specific applications are superconductors, multi-metallic materials, special alloys and super alloys. Multiple configuration possibilities allow remarkable dimensional reduction, wire flattening and also shaping in any kind of profile (round, oval, half-round, square, …). Sometimes multi stand rolling can even replace drawing, because the compression of material produces a more uniform and flawless internal structure, improving mechanical features and avoiding problems caused by drawing tension.

The “EFFE” series contains four models, which cover a wire reduction range from 25mm to 0.5mm, with working speed up to 150mt/min. Each model can be customized with exactly the number of stands needed for the process. Every stand can be upgraded with opening option, in order to come out with wire of any intermediate dimension. The machines are extremely simple and intuitive to work with: after wire insertion in the first stand, the process is performed automatically without operator control, so the worker can attend other activities. Thanks to a sophisticated development, total safety condition is guaranteed, keeping maximum accessibility and inspection facility. As a result of 50 years of experience, Invimec produces machines with preserving ergonomics, ease of use and minimum environmental footprint.

Invimec SRL

wire 2020, hall 11 booth H 30

Via della Cultura, 17

36050 Sovizzo (Vicnenza)Italy

Contact person is Elisabetta Ciccanti

Tel.: +39 0444 376245

info@invimec.com

www.invimec.com