06/02/2020

Wire bending parts fully digitized

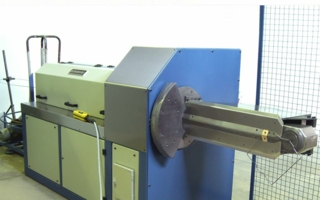

At the “wire” 2020, Bihler will present the efficient production of a wire bending part on the GRM-NC servo stamping and forming machine with a radial “Leantool” bending tool.

The “Leantool” radial system is perfectly suited for the simple and fast development of new modular bending tools for stamped and formed parts and wire bending parts. The system is fully digitized – from the planning and quotation stage with the “Bihlerplanning WebApp”, the simple design development of the tool with our bNX Software, the fast production of tool parts from standard parts all the way to the efficient production of the components. The result: Users benefit from tools with up to 70% standard parts, up to 70% lower cost as well as extremely short time-to-market for their developments. Setup times on the high-performance servo machine are less than one hour.

Reliable production processes

With integrated features for recording measured values and production data, the system is a self-regulating, self-controlling unit including control loops. Continuous monitoring allows trouble-free flow production from raw material to installation ready products with constant product quality. The high degree of digitization of the Bihler machine also enables easy networking and integration into intelligent production environments.

Otto Bihler Maschinenfabrik GmbH+Co. KG

wire 2020, hall 10, booth F 18

Lechbrucker Strasse 15

87642 Halblech/Germany

Tel.: +49 8368 18-0

verkauf@bihler.de

www.bihler.de