01/12/2019

When aesthetics and flatness are important

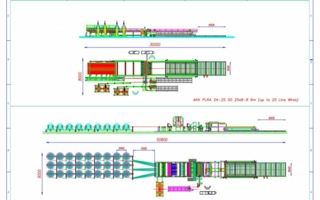

The “DH4010VGP” is the all-electric bending system with two independent heads capable of bending wires up to 10mm in diameter but also bars, flat rods, wire-wound resistors and tubes. The twin head makes this system particularly suited for bending parts having medium-to long development with many bends, particularly when high planarity is required.

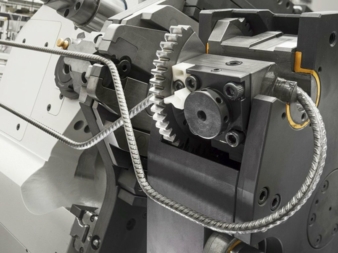

The two bending heads can work independently to make asymmetric parts. They have been entirely redesigned, capitalising on the positive experience of the “E-Flex” bending systems. Each head is provided with a twin bending turret which increases system flexibility with regards to the achievable bend types. The DH4010VGP can apply flexion bending on each of the two turrets, pressure die bending for minimum radii, edge bending, variable radius bending and strike bending on the same part. Various technical solutions provide answers to an ever-increasing number of needs.

The extra flexibility is demonstrated by the possibility of making parts which were once thought to be geometrically impossible. The reworking potentials, previously experimented on the E-Flex, are exploited to manage bending sequences very dynamically and avoid impossible geometries. Some parts deemed infeasible because of the collisions generated during machining can be made by DH4010VGP by modifying the order of various steps in the bending sequence. This clever yet simply capability facilitates the operator's work making it possible to process an increasingly higher number of complicated parts.

Part feasibility also passes through the possibility of minimising the length of straight parts and the DH4010VGP has answers for this issue as well. The handler that turns the wire stretch being processed can retract and clear the working field. This allows the bending heads to move very near each other and make very close bends.

Higher system productivity is guaranteed by optimised dynamics and cycles and also by the cutting unit: the wire cutting and end-forming unit is fitted on a carriage having linear movement independent from the heads.

This additional innovation contributes to increasing the productivity of the DH4010VGP by approximately 30% with respect to older systems.

The tried-and-trusted VGP3D programming and control software, with its three-dimensional graphic interface and easy programmed collision simulation and control system, is used.

BLM S.P.A.

Via Selvaregina, 30

22063 Cantú (CO), Italy

Contact person is Giovanni Zacco

Tel.: +39 031 7070200