08/10/2024 – Cold pressure welding

Welding trapezoidal wire

Cold pressure welding, well-established as a method of bonding round wire and rod, can also be used to bond other forms of nonferrous material, such as strip and profile. British company PWM Ltd has developed specialist machines to help manufacturers improve productivity, reduce operating costs and minimize waste.

Cold welding offers manufacturers a straightforward, fast and cost effective way of welding wire and rod, particularly when compared with electrical butt welding. Weld quality is excellent because the process produces a worked structure as opposed to the cast structure obtained in fusion welding. Also, there is no heat-affected zone with unsuitable properties. Nonferrous strip and profile are naturally more challenging to weld because the material surfaces are thin or an irregular shape.

Precision engineered products

PWM, which has been manufacturing and supplying cold welding equipment to wire and cable manufacturers worldwide for over 40 years, has developed specialist cold welders specifically for these types of material. Like all PWM products, these machines are durable, low maintenance and precision engineered to produce strong, reliable welds.

The “ST40” was the first machine PWM designed specifically for cold welding copper and aluminium strip used on armouring lines. The machine is mobile and can weld nonferrous material up to a maximum width of 45mm and a minimum thickness of 0.25mm, depending on the material properties.

To suit different applications and production set-ups, the “ST40” machine head can be positioned in either a horizontal position or a vertical position on the trolley. Quick and easy to operate, “ST40” is robust, low maintenance and user-friendly. It is also energy-efficient, since it is powered by an advanced air/hydraulic system and does not require any electrical power.

Welding trapezoidal wire

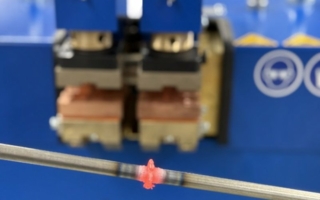

The company’s latest innovation is the “TR45”. Designed for welding trapezoidal wire used in the build-up of sub-sea cables, the machine will weld material up to 45mm². Some of PWM’s current machines, if fitted with special dies, can weld this type of complex profile but the company identified a need for a specialized machine that would be mobile, cost-effective and that would bridge the gap between its “HP200” cold welder and the larger, and more expensive, “EP500”.

The “TR45” has a footprint of 750mm x 610mm and is mounted on a trolley so it can be moved easily to the work area, saving effort and reducing downtime. Welding trapezoidal profile is almost impossible on an electrical butt welder; however, no set up is necessary with the “TR45”. No heat setting or gap setting needs to be made, as this is built into the die; and no spring pressure needs to be set. In addition, the machine is very straightforward to use enabling even untrained operatives to produce consistent high-quality welds. Once the machine is in position, the operator simply loads the material into the dies and uses the foot pedal to activate the cold weld process.

Like the “ST40”, the “TR45” is powered by compressed air, making it an energy-efficient option for manufacturers. The machine can be connected to a central air supply or a dedicated compressor, using a flexible hose with an inner diameter of 12mm.

PWM’s comprehensive range also includes small, hand-held manual machines suitable for fine wire from 0.10mm diameter, robust manual and powered models that can be used on a workbench or a trolley, and large, freestanding rod welders capable of bonding rod up to 30mm diameter.

As a cold welding specialist, PWM designs and makes its machines and dies in-house and tests all its products throughout manufacture to ensure total accuracy. Dies are individually hand-made in matched sets by the company’s skilled technicians. In addition to industry standard dies for wire sizes 0.08mm to 6.35mm, PWM produces custom-made dies for round wire, strip and profile.

The author is PWM managing director Steve Mepsted.

PWM (Pressure Welding Machines) Ltd

Units 1 and 5, Belmont Farm Business Centre

Bethersden, Kent TN26 3DY, England

Tel.: +44 1233 820847

sales@btinternet.com

www.pwmltd.co.uk