30/08/2023 – Joining / Welding

Welding machines for non-stop production

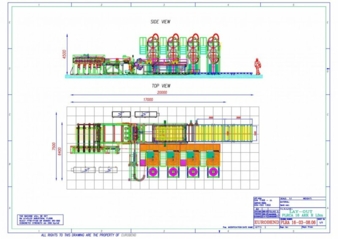

The welding lines of the “PL AKK” series are for the production of any kind of mesh, such as gabion mesh, welded wire fence panels, double wire mesh and rebar mesh.

They set new standards in mesh production, they say at Eurobend, since there are no downtimes and productivity is at least doubled compared to conventional welding machines.

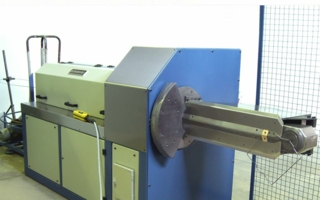

The innovative machine concept enables non-stop production through automatic change of mesh dimensions and mesh pitch. The wire feed from a single spool replaces all wire unwinding stations, while the feeding concept with redundant line and cross wire decoiling stations ensures continuous operation, without production interruptions when a coil runs out. Compared to conventional machines: when changing diameter, only one coil for the line and/or cross wires is changed.

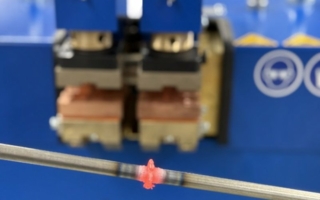

No mesh turning device is required: the cross wires are welded from above and below. No trimming is necessary: production of precision mesh from coil without wire overhangs. The patented “Automatic Wire Orientation System” (AWOS) allows the use of high-speed roller straightening modules for the line wire feeding. The AWOS system absorbs all the deficiencies in straightening quality that are common when straightening with roller straighteners ensuring perfectly flat mesh.

The flexibility offered by the AKK welding lines eliminates the need for a large stock of finished mesh, as with conventional welding lines. Optimal for just-in-time production (JIT) and efficient product changeover. Large and small batch orders, or even single orders, can be run sequentially with no downtime. Since its introduction numerous machines of this type are already in operation in Germany, Great Britain, Malta, Turkey, USA, Brazil and Japan.

Eurobend GmbH

Alexanderstrasse 1, 90547 Nürnberg/Germany

Contact person is Harris Athanassopoulos

Tel.: +49-911-94 98 980, sales@eurobend.com