04/09/2020 – Niehoff at wire China 2020

Uniform braid along the whole length

Maschinenfabrik Niehoff and Niehoff Machinery Changzhou Co., Ltd. (NMC), Niehoff’s Chinese subsidiary, will display at “wire China 2020” an “MMH 121 + RM 201” type multiwire drawing line, a “D 631” type high speed double twist bunching machine, both built by NMC, and the latest version of a “BMV 16” rotary braiding machine.

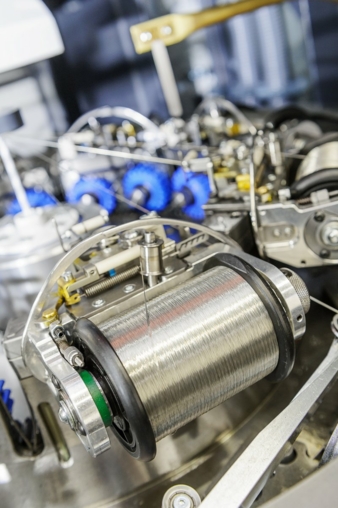

The “BMV 16” rotary braiding machine, the most recent version of Niehoff’s vertical lever arm rotary brading machines, features three patented innovations:

1) The 16-carrier machine can automatically increase the bobbin speed from 175rpm to a maximum value of 200rpm and reduce the frequency of the lubrication intervals. The result is an increased production output of 14%!

2) The machine keeps the coverage ratio of the cable always constant at the preset value, regardless of diameter changings of the cable to be braided. Thus, it possible to apply only as much braiding wire as necessary. This saves 15% material or even more!

3) Via WTC (Wire Tension Controlling) system and dancer position the machine controls the wire tension of the braiding bobbins, from full to empty condition. Thus, all braiding wires are applied to the product to be braided with uniform tension. The result is a uniform braid along the whole length of the product; such faultless shieldings are particularly required for applications in the area of autonomous driving.

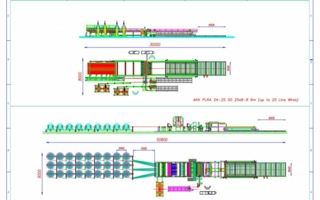

The “MMH 121 + RM 201” multiwire drawing line was made by NMC under Niehoff license. The mechanics of the drawing machine and all key-components were supplied by the Niehoff headquarters in Germany. The drawing machine is designed to draw simultaneously 14 wires on one level and can work with a maximum speed of 35 m/s. Some features of the line are high productivity, a low wire break rate and an energy saving operation.

The MMH multiwire drawing machines are designed for copper and aluminium wires and built on a modular principle. Therefore, MMH machines can be built ideally adapted to the specific tasks of customers. The wires drawn on MMH machines show highly homogeneous characteristics and narrowly tolerated properties along their entire length. Such wires can be processed to multiwire bundles with outstanding characteristics and are ideally suited for final applications or downstream processing into high-quality strands, ropes or braids.

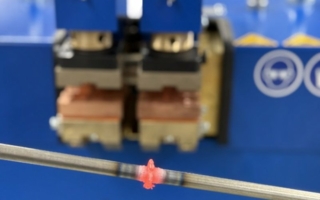

The “D 631” type double twist bunching machine was built by NMC under Niehoff license meeting the Niehoff quality criteria. Some features of the machine are high productivity, high-quality products and perfectly filled spools. All these features allow to tap considerable cost savings potentials: The one-bow design and the installation of an Eco-Bow ensure considerable energy savings in this machine compared to conventional bunching machines. Additionally, the D 631 allows to reduce material costs because the machine produces strands with very tight tolerances. This means that only the minimally required copper cross-section is used – not more! Finally, using this machine saves labour costs as the NBAT system and the precise functioning of the machine enable one operator to operate more machines at the same time.

The D 631 is designed for strands with a cross section of 0.09mm² to 6.00mm² and a steplessly variable lay length of 6mm to 100mm. The maximum number of twists is 6,500twists/min while the maximum linear speed is 300m/min.

wire China 2020, booth W1F27

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach/ Germany

Tel.: +49 9122 977-0

info@niehoff.de

www.niehoff.de

Niehoff Machinery Changzhou Co., Ltd.

Shanghai Sales Branch – Mr. Chen

Room 2302, Hong Kong Plaza,

283 Huai Hai Zhong Road

Shanghai 200021/P.R. China

Tel.: +86 21 61202800

info@niehoff.cn