02/06/2019

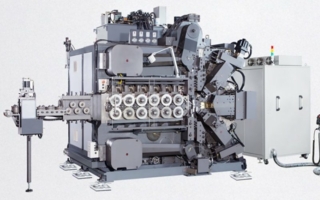

Ternium Barranquilla orders “VCC” line for bar mill

Columbian Ternium Del Atlántico SAS has commissioned SMS Group to supply and assemble a Vertical Compact Coiler line. The plant is located at the company’s bar mill in Palmar de Varela, Barranquilla.

Dusseldorf/Germany (SMS) – VCC technology is a solution for the production of compact, torsion-free coils. It is in increasing demand from reinforcing steel processors, supplier SMS reports. Compact coils are an important step in improving the packaging quality of the end product. They have predefined dimensions which, thanks to VCC, remain constant for all products manufactured on the same line. The size of the coils is ideal for storage, transport and handling. This is advantageous when processing coils on construction sites where the accumulation of reinforcement brackets and other reinforcement structures is limited in space, especially in urban areas.

These conditions had prompted Ternium to integrate the VCC technology into the existing bar mill. In future, the line will produce reinforcing steel from 8mm to 16mm diameter at a speed of up to 35m/s and produce 120 tonnes of material per hour with a coil weight of up to 3 metric tons. One of the most important characteristics of the VCC is the way coils are formed directly in the vertical position. Plant operators can thus dispense with rotary manipulators and at the same time reduce the process throughput time, as all coils are already reeled in the final alignment. After winding and cooling, the coils can be stored immediately. Since 1998, SMS has supplied 20 VCC lines worldwide with the Ternium line. Since 1950, the company has supplied a total of 543 lines for the production of wire, SBQ material and special grades, bars and commercial products.