17/09/2024 – Cable manufacture / Rotating machinery

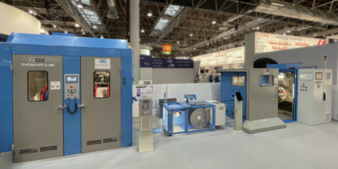

Tailored cables machinery solutions

Setic team committed to meeting the specific needs of each customer. Talk to their representatives about tailored cables machinery solutions. Come discover their latest advancements in high-performance cables machinery and sustainable solutions.

Setic design cables machinery for special, data communication and LAN cables machinery for automation, AI, robotics, aerospace and data analytics sectors and a major actor in the automotive wire equipment’s.

“We are pleased to announce the reopening of Gauder Group’s China operations, including a sales office in Shanghai. Our newly established structure Gauder Group Shanghai manufactures Setic made in China machines. These machines reply to the dynamic and critical Chinese and Asian markets, offering modern design, European quality, and performance standards. We fully assume local services in China to ensure competitive levels of support. This strategic move underscores our commitment to our Chinese customers and solidifies our position as a global leader in providing rotating machinery for the wire and cable industry. We eagerly anticipate building lasting relationships with our Chinese partners."

Pourtier manufacture heavy-duty rotating machines to produce all types of power cables: overhead, submarine, high voltage and extra-high voltage. Their team of experts will be available to discuss cutosmer specific needs.

Pourtier is the top choice when it comes to producing rigid, screening and planetary stranders, single twist cablers, and drum twisters for all types of energy cables from low voltage up to overhead, high and extra high voltage as well as submarine cables. Pourtier also offers complete know-how for process guarantee. All of these machines are designed and manufactured with the highest standards in design and manufacturing to produce all types of high-voltage and extra-high-voltage power cables. From overhead cables (including ACCC™ , ACSS-TW and ACSR-TW) to submarine or land cables AC type (using high quality Milliken conductor) or DC type (using large round compacted conductor or profiled “Keystone” wires).

“Our presence again this year at the ‘wire China’ show demonstrates our commitment for a better understanding of the Chinese market while observing the trends, the consumer needs, and present our new technologies. Pourtier connects its customers to all energy sources. Demand for Clean energy including improved infrastructures has been on the rise in the past few years, resulting in new market challenges. Pourtier has the most advanced solutions to meet these challenges for sustainable clean energy and infrastructure.

C2S Customer Services department is the ideal partner to maintain machines productivity and enhance products quality. Rich of a long and successful experience, the C2S - Services division has an overall efficiency booster to maintain wire and cable production lines productivity and products quality, whatever the brand of the equipment. C2S is being assigned spare parts, upgrades and maintenance projects, as well as transfer and restart operations of complete lines. Upgrades are a sustainable approach. By extending the life of existing machines, customers reduce their environmental impact by minimizing the need of new equipment. C2S solutions are a way to save Energy and “Go Green”. C2S is involved in smart factories in their Industry 4.0 processes.

Bow Technology sells customized bows for ALL sizes and ALL brands of double twist equipment. Bow is the answer to cable makers concerned by quality and long-life reliable bows for all brands of double twist machines from 560mm to 2,000 mm. With a comprehensive range of 650+ all sizes designs the division offers a global service from conception to production. The patented “Green Bow 2” is a closed-bow model ensuring important energy savings (up to 30%) on high-speed double twist bunchers (560mm to 800mm). It’s time now to take part of environmental questions towards a positive climate change. The team is ready to discuss any model matching the customer’s production needs.

wire China 2024, booth E1 F33

Setic Pourtier s.a.s

126, Rue de Matel

42300 Roanne, France

Contact person is Philie Colin

Tel.: +33 4 77 23 66 58

pco@setic-pourtier.com

www.setic-pourtier.com