02/10/2025 – Surface treatment

Stains on copper wire

For copper and copper alloy wire products, the surface quality is usually very important. Many types of surface defects may occur, and a particular set of defects are the so-called stains, discoloration spots or a discoloration of part of the wire surface.

Where do stains come from?

Stains can have many different causes, and the origin of stains is not always easy to find. To produce wire, the copper or copper alloy undergoes many different process steps from casting, rolling and wire drawing. The appearance of stains may become visible at a different, later stage in the production than where the defect had occurred.

To help identify the root cause of a stain, companies such as Q8Oils and their Research and Development department has developed a test to analyse the stain in more detail. With such a test, a stain on the surface of a copper or copper alloy can be investigated and an analysis can be made its composition. Historically, stains on copper alloys typically originate from oxidation of copper, or carbonaceous matter, or a copper sulphur substance. With this kind of tests, these different natures can be distinguished from each other.

How is such a test executed?

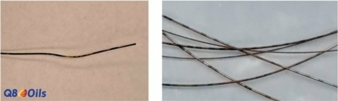

At Q8Oils R+D facilities the test is conducted with four pieces of wire that contain stains spots or larger stain areas. One-piece is always kept untouched as reference and the other three wires are each partly submerged into a chemical.

Each of the three samples is dipped in one of the investigation liquids (A, B & C). Then the three differently treated wire samples are visually inspected together with the reference wire to see if the stain is removed or not. In case of fine wire and/or small stain spots a microscope could be required. With the matrix table below the nature of the stain can be determined.

Understanding the different kind of stains?

When the nature of the stain is known, the next step of course is to investigate at which stage in the production the stain is initially formed. Copper sulfide stains may originate from tramp oil contamination or bacterial infection. Copper oxide can be formed at high wire temperatures in the presence of oxygen (air). Examples are:

– wet wire exiting the drawing machine

– insufficient inhibitor in the drawing or annealing solution

– excessive temperature due to high reductions

– high speeds

– not enough lubrication

– inadequate cooling

– or combinations thereof

Stains with carbonaceous nature can be formed when too much carbon containing material is present at the wire surface at high temperatures. An example is the case where too much organic matter is present in the annealing process, resulting in the phenomenon that not all the organic matter can evaporate, and remaining residue starts to carbonize at the wire surface.

How to choose an ideal partner for lubricants?

When selecting a partner to optimize a company's lubrication processes, it is beneficial to choose one that collaborates closely and actively seeks ways to enhance casting, rolling, and wire drawing operations. A crucial element of these improvements is a deep understanding of potential defects, such as staining. Specialized tests, like those offered by industry experts Q8Oils, help identify the root cause of stains on copper or copper alloy wire.

Kuwait Petroleum (Belgium) N.V.

Q8Oils - a subsidiary of the Kuwait

Petroleum International Group

Petroleumkaai 7

2020 Antwerpen/Belgium

Contact person is Kristina Chekhut

Tel.: +32 484123085

krchekhu@q8.com

www.Q8Oils.com