20/01/2020

Reducing costs by using highly performing lubricants

Nowadays, people are more and more concerned about environmental impact and protection, and this includes the wire drawing industry. Of course, reducing total costs by using highly performing lubricants is important but the responsible use of such products is also a main topic.

When looking for the most efficient lubricating solution, Condat’s ambition is not only to guarantee a high level of performance, it is also to provide support towards responsible performance that takes into account social and environmental issues. To achieve this, Condat provides solutions that allows the customer to increase the productivity and secure the working conditions all whilst respecting personnel and the environment.

Increase your productivity

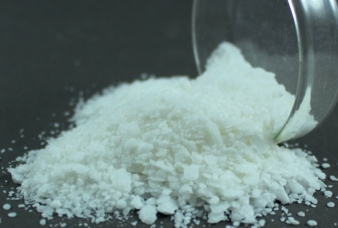

Increasing productivity responsibly means, for example, drawing faster, thanks to the Condat “Vicafil Sumac&rdquo range which has a higher softening point compared to usual sodium soaps. It enables efficient drawing in the most demanding operations such as the production of spring wire, PC strand and steelcord.

It also means less die wear when using, for example, the “VicafiI TF” range of calcium soaps. These formulas are designed to deliver the correct amount of lubricant between the wire and the die by providing sufficient, homogeneous coverage of the wire.

Reduce dust in workshops

Securing your working conditions by reducing dust in the workshops, for example, is a necessity. Dry lubricant used in the wire drawing industry has the potential to generate dust. The problem of dust in the workplace is well documented, whether it is the risk of fire due to ignition of a combustible dust cloud or increased exposure risk for operators resulting in dermatitis, respiratory tract irritation or potential long-term health effects due to long term exposure to lubricant additives such as borax. In addition to these hazards, lubricant dust in the workshop can also be an indication of non-optimal lubrication with an associated economic cost. The lubricant needs to be in the die or on the wire surface to perform. Lubricant in the form of dust in the environment is therefore wasted, thus generating additional costs.

Use of a suitable dry drawing lubricant, determined according to the client’s specific application will significantly reduce the amount of dust generated in the workshop whilst also reducing overall wire

drawing costs. Lubricant grain form, grain size, composition and thermal profile, all have a significant impact on dust formation.

In addition, many of Condat’s calcium, sodium and mixed soaps are also available in the form of pellets; this form significantly limits the release of fine particles during filling of the soap box.

Improving the adherence of the lubricant to the wire surface as the lubricant cools is also the key to significantly reducing the dust generated at the capstan. The use of lubricants with an unsuitable melting point or too high or too low fat content will generate residues at the die exit and at the capstan which can result in dust generation. Fully understanding the requirements of the application, in function of the steel type, surface preparation, reductions, speed, cooling efficiency, ... enables Condat to recommend a lubricant with a chemistry best suited to the demands of that application.

Secure your working conditions and ensure neutrality of products

Guaranteeing responsible performance also means ensuring the neutrality of products. Highly efficient, Condat’s lubricants and surface treatment products have been thus developed to minimize hazardous components, to meet the latest environmental legislation and even anticipate more stringent upcoming regulations.

With a modern, well-staffed laboratory and technical expertise in all fields of industrial lubrication, Condat works closely with its customers to offer developments suited to their needs, and is committed to improve the security of its product formulas whilst keeping the right balance between safety and performance. Borax-free and titanium dioxide free dry drawing soaps, as well as borax-free surface treatments, have been developed by researchers to meet your productivity challenges for all type of wire drawing applications. Discover, amongst this offer, the high performance borax-free sodium soap “Vicafil Santale 6” and non-reactive surface treatment “Vicafil TS 7113”, both in use at top wire drawing manufacturers.

About CONDAT

Condat is an independent company with international presence, specializing in the field of industrial lubrication. For over 160 years, it has adapted its products to the specific needs of each market (drawing, cold heading, metal working,…) and has developed a wide range of soaps, greases, oils,… In the field of wire drawing, Condat’s lubricant range is recognized as a world reference. Its “Vicafil” and Steelskin” range gathers together the widest choice of wire drawing soaps, surface treatment, neat and soluble oils, degreasing products, ...

Condat

wire 2020, hall 10 booth A 52

104 avenue Frédéric Mistral

38670 Chasse-sur-Rhône/France

Contact person is Nathalie Vidal

Tel.: +33 4 780737-11

nathalie.vidal@condat.frwww.condat.fr