15/11/2018

Profitable innovations for cold and hot forming

Sacma’s “SP270-WF300” is an alternative to fully integrated warm forming machines. The new six dies system processes forming parts up to 300°C. It works with a patented “S-Feed” wire feeding system, driven by servomotor and allowing precise and reliable cut-off operations.

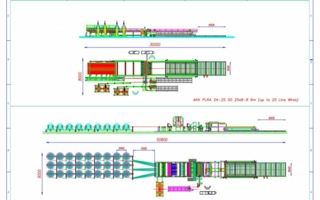

Sacma group has presented the header model “SP270-WF300”, which package consists of a light “WF” version, as alternative of the fully integrated warm forming machines. This six dies header forms parts at temperatures up to 300°C. It has the patented “S-Feed” wire feeding system, driven by servomotor, and allowing a precise and reliable cut-off operation. The header is designed for Industry 4.0 and equipped with the Sacma “Load Matic” made by Brankamp. The 7th transfer finger has a pneumatic opening, to be used for quality management in connection with the loading control.

The S-Feed wire feeder, first mechatronic application of Sacma Group, is joined by the brand-new S-Transfer. The company's research+development department has created a transfer driven by linear motors allowing the operator to set-up and manage all the operations from the touch screen panel “SC Matic”. It provides additional functions to run difficult parts requiring dedicated set up for a perfect transportation. A presentation will be dedicated to the new S-Transfer unit explaining the concept and the features. Sacma points out that the S-Transfer is also the result of the synergy with Ingramatic in the application of servomotors for different functions. The sharing experience strategy makes the new projects safe and durable since the beginning. The S-Transfer will be progressively introduced in the Sacma headers in short period.

The group extends the product line by introducing the new six dies combined headers model “SP59” and “SP59-C”, 24mm wire cut off, DKO 180mm and 110mm, meeting the demand of automotive industry to produce ever more complicate threaded parts. The Sacma combined headers maintain the performances of the Progressive headers, from which they derived.

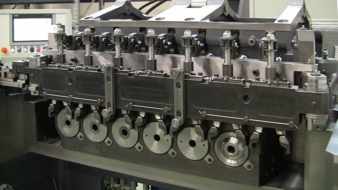

Sacma Group member Ingramatic is a leading company for designing and manufacturing thread rolling machines. The modular “I-Thread” machine line provides features like the motorisation of the die match and the single starter units driven by torque motor motion and the patented double starter unit driven by servomotors. These two types of starter units have, as a standard function the self-learning adjustment of the starter fingers to make easy and quick the set-up of the blank introduction. Ingramatic is the first worldwide company having engineered a solution for the whole range of machines from “M1” to “M33”.

During the “wire” show Ingramatic will have a world premiere, showing the smallest threader inspired by the I-Thread concept, the model “RP020” for the high-speed production of very precise miniature screws. The machine is equipped with the latest technologies available as an innovative tool holder, an introduction system driven by a linear torque motor and a slide running on linear guides (with ball circulation skates) in order to ensure high accuracy for rolling operation. The machine is equipped with the same advanced functions of the I-Thread machines, like the self-learning adjustments of the starter unit, the frame made of spheroidal cast iron and the SC-Matic interface for the fully motorised adjustments.

Sacma Group

Tel.: +39 02 994521