20/12/2021 – Reduce operating costs and improve weld quality

Precision-engineered cold welding machines

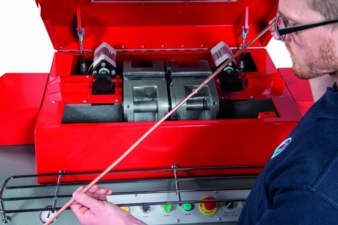

The comprehensive Pressure Welding Machines (PWM) product range includes hand-held machines and machines that can be used on a workbench or supplied with a trolley, as well as large free-standing machines for welding rod. Both manual and powered cold welders are available, with capacities ranging from 0.10mm to 30mm.

As a specialist designer, manufacturer and supplier of cold welding equipment for over three decades, British company Pressure Welding Machines (PWM) offers wire and cable manufacturers an unrivalled range of technically-advanced, British-made machines and dies for a variety of applications.

Innovation in cold weld technology

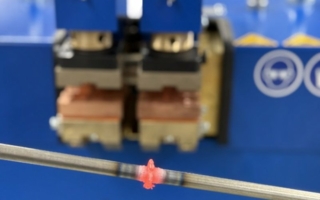

Recent developments include the “ST40”, the first machine of its kind designed specifically for welding nonferrous strip. he air/hydraulic-powered machine can weld strip as thin as 0.2mm, and as wide as 45mm, depending on the properties of the material. Like all PWM cold welding machines, the ST40 is precision engineered to produce high-quality, reliable welds every time, helping manufacturers improve uptime and reduce waste.

PWM specialises in custom-made dies, which can be made for round wire or profile, including complex trapezoidal and Z wire profiles used in the build-up of sub-sea cables. These can now be produced for sizes across the range of PWM’s manual “M101” and air/hydraulic “HP100” and “HP200” cold welding machines up to 33mm², and up to 170mm² on the “EP500” electro/pneumatic rod welder.

Energy-efficient systems

While electrical butt welders use a lot of power to bond large rod sections, cold welders are less demanding. PWM’s energy-efficient machines can weld nonferrous material up to 30mm diameter using advanced hydraulic and pneumatic systems, yet consume little energy. The largest machine in PWM’s range, the “P1500” model, can weld 25mm copper and 30mm aluminium. Driven by three hydraulic pumps, the machine only requires electrical power for the 11kW pump motor. The smaller pneumatic “EP500” model, for rod 5mm to 15mm, can be connected to either a central air supply or a dedicated compressor. Only the control system, which the operator uses to set the weld parameters, needs a single-phase electrical supply. No set up is necessary and the “P1500” and “EP500” are user-friendly, quiet and clean.

Portable options

For manufacturers who require a powered cold welder for small wire sizes, PWM produces the “HP180” model, which enables any member of the workforce to weld wire up to 1.80mm in diameter without effort. The welding head of this small pneumatic machine is mounted on a trolley, but it can also be detached and used hand-held (within the limit of the two-metre air supply line). PWM also makes a version contained in a compact 400mm² carry pack. Portable machines are also available for larger wire sizes, 1.00mm up to 6.50mm.

Manual models

PWM’s manual range includes the popular “M101”. Designed for material 1mm to 5mm, the “M101” is a robust, heavy-duty, low maintenance machine that will weld wire, strip or profile. Smaller, hand-held manual welders cater for wire within the range 0.10mm to 1.80mm. PWM also produces two larger manual machines for the same wire sizes, which can be used on a workbench or supplied with trolleys.

Industry-standard dies

Industry standard dies are produced for wire sizes between 0.08mm and 6.35mm. PWM can also make dies to weld two different sizes of material, enabling manufacturers to join different wire sizes together quickly when changing spools.

PWM is the only company producing British-made cold welding equipment, designed and made at its facilities in Kent, UK. Video demonstrations of all PWM’s machines can be viewed on the company’s website.

PWM (Pressure Welding Machines) Ltd

Units 1 and 5, Belmont Farm Business Centre

Bethersden, Kent TN21 3DY, Great Britain

Contact person is Steve Mepsted

Tel.: +44 1233 820847

pwm@btinternet.com

www.pwmltd.co.uk