30/06/2022 – Shaping change in the automotive industry with metal mesh

Powerful lightweights

From driverless vehicles to electro mobility: A profound process of change is altering the automotive industry. Manufacturers and suppliers need to rethink technologies. Innovative processes and products are what is needed to secure competitiveness. Woven materials can play a key role in this area.

Although they are already widely used in vehicles – often unseen – their potential is far from exhausted. High-precision, formable, and resistant to high pressures, temperature fluctuations, and vibrations: With their performance range, woven structures enable previously unthought-of solutions to many urgent requirements. As a sought-after development partner and system supplier of components and parts made of mesh, the global GKD Group (GKD) based in Germany possesses more than 40 years of application experience in numerous central aspects of the automotive industry. Metal and hybrid meshes from GKD filter, laminarise, protect, conduct, or shield against electromagnetic waves. Many reputable vehicle manufacturers and suppliers place their trust in the leading and visionary solution competence of this family-run business, now under management in its third and fourth generation, when it comes to shaping the technological revolution.

The transition from conventional to electric drive systems is reflected in growing expectations of the drive train, gear design, and hydraulic systems. The requirements for materials and products are accordingly complex: Resistance to heat, corrosion, and soot clogging from condensate as well as minimising pressure loss are often just as important as efficient EMC shielding, conductivity, reliable particle protection within the given limits of installation space, weight reduction, formability, and regenerability. In solving these typical challenges, GKD mesh is often superior. By reliably protecting the drive, engine, and electronics, and optimally distributing and metering fuel, gas, hydraulic fluid, or additives, it can help to achieve that urgently sought technological advantage. Alongside the standard meshes that were primarily used in the past, such as square mesh and twilled dutch weaves, today's innovative meshes from GKD enable virtually unlimited possibilities: Flow-optimised weaves such as the three-dimensional Volumetric with a significantly increased volume porosity or optimised dutch weaves with extremely high dirt-holding capacity combined with very good flow rates are the key to significant increases in efficiency. Conductive and formable shielding meshes permit new dimensions in the protection of components and car occupants. Through conductiveness, for example, smart wire meshes open up additional functions like capacitive measurements, sensors, air flow metering, or even thermo-management of batteries. With specific combinations of materials, hybrid meshes offer the possibility of combining desired properties to achieve a perfect match. In addition to stainless steel, GKD processes extremely heat-resistant types of steel and special alloys as single or multi-ply high-tech mesh designs constructed for specific applications to form DKS strips, die-cut and machined parts.

Great potential

The enormously versatile range of properties of metal mesh gives engineers and designers great freedom in developing new solutions. The Volumetric metal mesh, for example, is used on both the hot and cold side of the engine in exhaust gas after-treatment. In low-pressure exhaust gas recirculation, its pore distribution enables retention of different sized particles, thereby ensuring that downstream components are protected against damage. What's more, the laminarising effect of Volumetric in gas filtration minimises pressure loss in the exhaust gas flow and thus reduces fuel consumption and carbon emissions. This homogenization of flows qualifies metal meshes for uses such as flame screens or increasing the effectiveness of interior heating systems in electric cars. GKD meshes can also set new standards as thermally conductive mats for the thermo-management of vehicle batteries. For valves and inductors, metal mesh offers protection against clogging and soiling – in the brake or fuel system as well as in hydraulic control, in the gears, or oil circulation. Generally, metal and hybrid meshes offer new solutions thanks to their low weight and the ease with which they can be shaped into 3D designs. Pioneering possibilities for metal mesh are also evident in the field of hydrogen-powered engines and fuel cells: In addition to thermo-management or shielding, the mechanical support of electrodes or membranes offers interesting possible uses. In hydrogen generation, metal meshes used as cathodes provide new opportunities as well. Furthermore, shape memory mesh promises a wide range of potential applications as a powerful actuator with minimum space requirements and weight.

Pioneering solutions

Suppliers with extensive skills in designing application-specific mesh components, automated manufacturing processes, and a keen understanding of the vehicle as a whole are therefore popular development partners for manufacturers and suppliers. GKD grew early on from a supplier of goods sold by the meter to a parts supplier and component manufacturer for the automotive industry. Landmarks in the birth of this collaboration in the early 1980s were strips for airbag production and maintenance-free door hinges. Customized protective filter screens for safety systems such as ESP and ABS as well as gear filters followed shortly after. Meanwhile, the company amassed a long reference list of wind tunnels, which were fitted with anti-turbulence screens made of metal mesh for renowned automotive manufacturers, Formula 1 teams, and the international aviation and aerospace industry. The decades of experience in working with manufacturers of batteries also made GKD the first choice of partner when it came to developing battery technology in the cars of the 1990s. Mesh designs developed for specific applications to be used in batteries and fuel cells as well as decades of collaboration with leading aircraft manufacturers and producers of consumer electronics in the field of EMC shielding are the reason for GKD's outstanding development competency in pioneering e-mobility solutions with metal and hybrid mesh. In 2007, GKD set a further benchmark that still stands today with the development of Volumetric mesh for exhaust gas recirculation. Around the world, most automobile manufacturers use this type of mesh in the exhaust train of diesel and petrol engines under the Euro 6d standard. Plus, GKD is working intensely with renowned partners from industry and research on innovative solutions for combustion, hybrid, and electric engines.

Everything from a single source, from idea to product

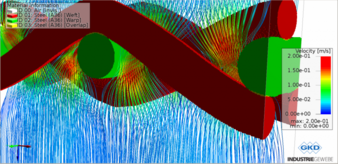

GKD offers what is needed to achieve the required efficiency in development and implementation from a single source: engineering, weaving, forming, automated camera inspection, heat treatment, prototype construction, and all common joining and cutting technologies – if necessary under defined clean room conditions. For coating and plastics injection molding, customer-specific solutions are provided . GKD combines decades of experience in prototype construction with ultra-modern CFD technology in order to optimise the geometries of meshes or customer components. With the simulation environment IT developed in-house, parameters such as porosity, separation efficiency, or flow are mapped and optimised on the basis of virtual models to save time and costs. Examples include applications such as reducing the loss of pressure in the exhaust line or improving the efficiency of interior heating systems in electric cars. Fast feasibility analyses of components and prototype construction in-house also contribute to the efficiency of the development process. Fully automated manufacturing as well as continuous camera inspection for 100% quality control of pore accuracy, contours, and connections provide assurance that all of GKD's production sites meet the tough requirements of the automotive industry. The highly reliable supply chain plays a part in this, too: It can be adapted quickly to any changes in the various manufacturing steps. At the same time, the global organisation of the GKD Group, based on a division of labour, generates a value chain geared towards customers' needs. Group-wide knowledge transfer among all divisions leads to solutions that make GKD metal mesh the pace setter for pioneering product optimisations and new developments. Through creative solutions, innovative manufacturing processes, and strong processing competence, GKD regularly pushes the boundaries of what is possible. The result is solutions developed from metal or hybrid mesh at an exceptional technical level which respond to the urgent issues of the automotive industry.

GKD Group

Metallweberstrasse 46

52353 Düren, Germany

Tel.: +49 2421 803-0

processbelts@gkd.de

www.gkd-group.com

About GKD Group

As a privately owned technical weaver, GKD Group is a world market leader in metal, synthetic and spiral mesh solutions. Four independent business divisions bundle their expertise under one roof: Industrial Mesh (woven metal mesh and filter solutions), Process Belts (belts made of mesh and spirals), Architectural meshes (façades, safety and interior design made of metal fabrics) and “Mediamesh” (Transparent media façades). With its headquarter in Germany and five other facilities in the US, South Africa, China, India and Chile – as well as its branches in France, Spain, Dubai and worldwide representatives, GKD is close to markets anywhere in the world.