20/11/2023 – Wire processing / joining / welding

Pioneering in automation solutions for mesh production

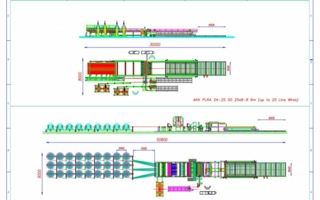

The wide product range of Eurobend GmbH includes sustainable solutions for the production of almost all types of wire welded mesh for the construction and wire industries.

More specifically, their mesh welding lines are recognised by their cutting edge design features and they are well established for their efficiency and reliability. Eurobend is committed to continuous improvement, and this is reflected by the new ideas presented; increasing the automation, focusing in personnel safety and minimising of human intervention making the offered machines the leading power in the global market. One of the innovative features, available as an add-on unit on almost all mesh welding lines manufactured by Eurobend, offers fully automatic and precise stacking of the produced meshes placed on the mesh conveyor either on pallets or directly on it..

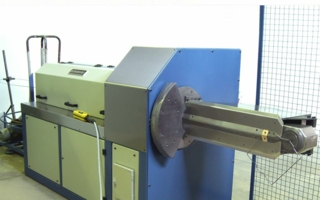

The “auto-palletizing systems” as the name states, are automatic robotic precision “pick-and-place” units with automatic pallet insertion and positioning that work in conjunction with the welding lines, without affecting either the output speed or any other production parameter of the machine. The unique design, together with the – practically – unlimited programming capabilities and the exceptional flexibility of the “auto-palletizer”, allows the use of the unit on almost all Eurobend mesh welding lines regardless of the size, version or mesh type produced. Just to name a few, the “auto-palletizer” can handle fencing, gabion and any type of industrial mesh, as well as construction and precast mesh.

The operation of the system is divided into the following steps:

The operator places the pallet on a specified location outside the machine working area (if a pallet is used for the stacking, as the system can stack the produced meshes also directly on the mesh conveyor)

On the next step, automatically the pallet(s) is forwarded to the mesh stacking area of the welding machine.

Once the programmed number of meshes are positioned accurately on top of each other, forming a bundle, the system is forwarding the formed mesh bundle outside the working area of the machine for pick up.

Depending on the mesh dimensions, the “auto-palletizer” can stack two bundles in parallel, either by loading two pallets sequentially or forming two mesh bundles on the mesh carrier.

Due to minimal operator intervention during the stacking process, the “auto-palletizer” achieves the maximum on safety standards.

Furthermore, due to synchronised operation of the system with the welding machine, a new pallet can be placed with safety while the unit is in operation (as the pallet is placed outside the working area of the machine) providing uninterrupted mesh production.

Eurobend GmbH

Alexanderstrasse 1, 90547 Nürnberg/Germany

Contact person is Harris Athanassopoulos

Tel.: +49-911-94 98 980, sales@eurobend.com

www.eurobend.com