19/04/2023 – Niehoff at Interwire 2023

Perfect braiding and bunching

Maschinenfabrik Niehoff and its subsidiary Niehoff Endex North America, Inc. (NENA) will be exhibiting at the “Interwire 2023” trade fair on stand 841 a braider type “BMV 16” and a “D 802” type double twist bunching machine.

Niehoff After Sales Service offers, Niehoff Original+ components and the “myNiehoff” app will also be on display at the stand. They contribute to further increasing the productivity and production reliability of Niehoff machines and to sustainably reducing operating costs.

Machines on display

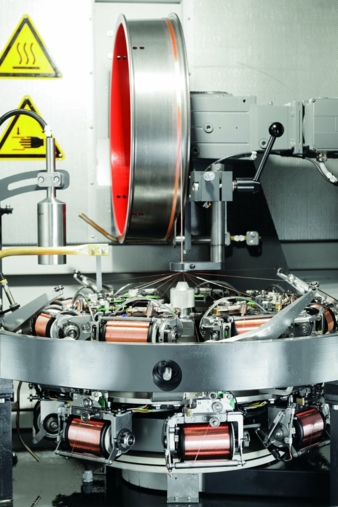

The braiding machine type “BMV 16”, a vertical lever-arm rotary braiding machine with 16 carriers, has a number of special features compared to conventional braiding machines. The “BMV 16” can automatically accelerate the bobbin speed from 175rpm to a maximum value of 200rpm. This allows the braiding performance to be increased by 10%. At the same time, the frequency of the lubrication intervals is reduced depending on the slideway temperature. This means that less lubricant is used and less oil contamination occurs on the braids. A further feature is that Niehoff’s “WTC” (Wire Tension Control) system ensures that all braiding wires are applied to the product to be braided under uniform tension from the full to the empty bobbin. As a result, the braiding machine produces flawless shielding, which is needed for more and more applications. In addition, the braider keeps the braiding coverage ratio of the product to be braided constant at the preset value. Since only the absolutely necessary amount of braiding wire is applied, up to 10% material can be saved. The braiding coverage can be documented and provided to the customer.

Multiple monitoring systems enable unattended operation over longer periods of time and without frequent operator intervention. With the help of the “myNiehoff” app, users can monitor machine and process data online.

The “BMV 16” is designed for processing of bare or plated round or flat wires made of copper, aluminum or stainless steel with single wire diameters from 0.02mm to 0.56mm (for Cu soft) as well as artificial yarn and fibers.

In addition, Niehoff will show a double twist bunching machine type “D 802”. The machine is designed for the bunching of plated and bare wires or the stranding of insulated wires and can be used to produce (copper) strands with a cross-section of 0.25mm² to 16.0mm² and a steplessly adjustable lay length of 15mm to 160mm. Insulated wires up to an outer diameter of 7.5mm can be stranded. The maximum production speed is 300m/min, the maximum number of twists is 5,000tpm.

Like all D-series machines, the “D 802” features the proven energy-saving single bow design (Eco-Bow) and is equipped with an energy-saving rotor drive of energy class IE3 and an adjustable fan drive in the soundproof cabin. More features include wireless telemetry for all signals including encoders – the absence of brushes increases the production reliability and simplifies maintenance – and an automatic traverse equipped with a flange detection system that enables perfect spooling. This allows the spooled cables to paid off without tangles or damage, even at high speeds. Bearing temperature, the vibrations of the cradle and the quality of the production process are monitored. Using the “myNiehoff” app, customers can monitor machine and process data online.

The author Konrad Dengler is freelance journalist from Großenseebach, Germany.

Interwire 2023, booth 841

Maschinenfabrik Niehoff GmbH+Co. KG

Walter-Niehoff-Strasse 2, 91126 Schwabach, Germany

Tel.: +49 9122 977-0

info@niehoff.de

www.niehoff.de

Niehoff Endex North America Inc.

1 Mallard Court, Swedesboro, NJ 08085

Tel.: +1 856 467-4884

sales@niehoffendex.com

www.niehoffendex.com