21/10/2019

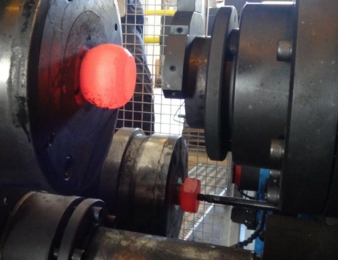

New hot forging line

Videx has launched a new “Hot Forging line” which consists of six to ten machines. This line replaces the traditional separate forging presses and trimming operation and is fully automated with no robots.

The line is comprised of the following machines:

– Bar-Feeder and Bar-Shear, cutting the bars to length (the line may also start from coils)

– Chamfer machine with optional turning stations

– Extrusion machine, extruding the chamfered end from major to pitch diameter

– Induction Heating machine (not made by Videx)

– Double Blow, Solid Die, five-stations forging machines; one feed station, two forging stations; and two ejecting stations

– Cooling Conveyor

– Thread Rolling machine

The forging machines are available in 300, 400 and 500 metric tons, for M-20 to M-48/M-64 and M-76 in length of 200mm to 1,000mm under head. The head (hex for example) is formed in a closed die and it does not need trimming. The production rate is four to six parts per minute.

Operation sequence

The chamfered and extruded bars are fed into the die by a pneumatic piston. The feed dial indexes the parts to the first forging station, which upsets the parts and breaks the scale and then to the second forging station, to complete the head shape. After heading the parts are ejected to a conveyor which transfers them onto a cooling conveyor on which they cool before they go into the thread rolling machine.

The machines are available either independent or as complete lines.

What makes it different

It is the first and only real commercial solution, starting from raw material and ending by a sellable product. This line is the fastest of its kind. The machine construction enables production of long bolts, up to 1,500mm. No trimming needed when forging in a closed die, thus saving material and time, and making the process more “Green”. In-line cooling, saves intermediate storage and handling. Single panel controls the entire line, requiring just one operator to run the whole line.

Videx Machine Engineering Ltd.

wire 2020, hall 16 booth A 71

20, Shabazi Street, 5623107 Yahud/Israel

Contact person is Yair Wiesenfeld

Tel.: +972 3 5364801

videx@videx.co.il

www.videx-machine.com