21/10/2025 – Engineered to maximize production efficiency with automatic cut and transfer

New “Dual Head Spooler”

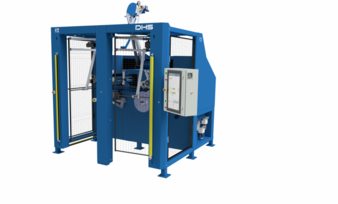

Reelex Packaging Solutions, innovator in sustainable wire and cable packaging technology, unveiled its new Reelex “Dual Head Spooler” (DHS) at Interwire 2025 in Atlanta/USA.

The “DHS” is a semi-automated, dual-headed spooling machine designed to elevate production efficiency, user experience, and safety. Engineered to support the demands of high-volume manufacturing environments, the Reelex “DHS” features a fully automatic cut and transfer system between two spindles, allowing for continuous operation with minimal downtime.

“Designed with operator safety, user-friendly controls, and greater productivity in mind, our DHS redefines what is possible in wire and cable packaging,” said David Gerhart, President and CEO of Reelex. “The Reelex ‘DHS’ fills a gap that exists in today’s marketplace between old, outdated machines that don’t meet today’s standards, and larger, fully automated machines at much higher price points. This is the perfect time for our new DHS and we’re anticipating a lot of interest.” As an industry leading packaging solutions provider, Reelex continues to innovate with more products to help serve a broader customer target.

Key features of the Reelex “DHS” include:

Speed: Automatic cut and transfer between spool heads allows the “DHS” to operate at high speeds at the end of a jacketing line for non-stop production or rewinding depending on your production layout. The “DHS” is compatible with standard or custom spooler shaft kits to handle all of the most common spool designs, and an adjustable wire guide to handle multiple cable types with ease. The DHS can be configured with an optional automatic stretch-wrap module to protect the spool and keep the product intact.

Ease Of Use: The user-friendly, high-definition touchscreen HMI allows the operator to set up the machine via a recipe-based product selection screen, allowing for quick product changeovers. It is Industry 4.0 capable with more than 100 preset recipes, network connectivity capabilities for data analytics, and on-screen visual feedback providing easy troubleshooting and diagnostics of machine status.

Safety: The “DHS” can be safely operated by any machine operator, and is equipped with integrated safety guarding that automatically isolates the rotating spooler shaft to protect the operator while still maximizing productivity. The “DHS” meets the most stringent ISO safety design standards, as well as Safety PLC controls for intelligent monitoring and emergency response.

The Reelex “DHS” specifications

Line Speed (Max.): 1,500ft/min

Spools Per Hour: ~90 (1,000/ft)

Transfer Time: ~10s

New G5 Controls Platform

Optional Stretch-Wrapper Module

Reels: The Reelex “DHS” accommodates the most common reel sizes and designs in the market today based on information from our global partner, AXJO Plastics. The DHS uses spools compatible with the most common designs used by other spooler brands in the market.

Availability: The Reelex “DHS” is available for ordering today. Shipments will begin later this summer.

“Productivity and safety have always been at the core of what we offer at Reelex, but the “DHS” represents a significant leap forward in automation and user experience,” said Gerhart. “This machine is built for modern production floors – it’s smart, efficient, and incredibly easy to use.

In addition to the launch of its “DHS”, Reelex was showcasing its industry-leading “S320e” hybrid coiler and “POD” Cable Delivery System at Interwire 2025. Both machines were introduced at the “wire Dusseldorf” event in 2024 and have quickly been adopted by companies around the world.

The Reelex “S320e” machine produces both patented Reelex coils and traditional spools, with a changeover time of less than 10min. The “S320e” is great for high mix, low volume environments that have a need for production flexibility, small footprint, and ease of use. With a smaller footprint, faster cycle times, and enhanced energy efficiency, the Reelex “S320e” addresses the industry’s growing demand for flexible, sustainable, and reliable packaging solutions.

The Reelex “POD” cable delivery system features a motorized payoff and dancer integrated on a safety guarded compact frame. Unlike traditional coil packaging methods, the REELEX S320e with POD not only minimizes the use of materials, but also improves package consistency and durability, reducing damage and waste throughout the supply chain. The S320e and POD are available to ship within ~6 weeks of purchase.

Reelex Packaging Solutions, Inc.

39, Jon Barrett Road

Patterson, NY 12563/USA

Contact person is Heidi Davidson

Tel.: +1 914 441-6862

marketing@reelex.com

www.reelex.com

About Reelex Packaging Solutions

Reelex Packaging Solutions is a global leader in packaging technology for the wire and cable industry. Known for its patented twist-free, tangle-free Reelex packaging, the company is committed to innovation, sustainability, and providing solutions that enhance productivity across the supply chain.