08/08/2019

More than only to support the human colleague ...

You can definitely rely on robots. The sales figures year by year increase, and the versatility and application range, too. Soon enough, robots will use artificial intelligence to catapult industrial production into spheres that were previously hardly to imagine.

The Asian-Australian market relies heavily on their support. 2018 was demand for 260,000 units, then 71,000 in Europe and 49,000 in America. China remains by far the largest customer – according to IFR estimates, it acquired 133,000, followed by Japan with just over 52,000 units. The USA, the third largest market for robots, made a notable 15% leap to a total of 38,000 units last year. “The North American countries – US, Canada and Mexico – represent the second largest operating base of industrial robots in the world after China,” says Junji Tsuda, president of the International Federation of Robotics IFR. While many major robot system integrators came from North America, most major robot manufacturers are located in Japan, Korea and Europe.

Driving force behind the ever-increasing demand is the automotive sector, where robot use is gaining momentum. Because the advantages are obvious: These include increased productivity, production reliability, stable processes, “closed” production processes – with a finished part – and linking also in difficult positioning. However, robots are usually “lone warriors”. They are often separated from humans by a safety fence.

But this is likely to change with the use of artificial intelligence in the future, when robot and man work shoulder to shoulder. What would have been considered science fiction years ago is slowly but surely becoming reality. Investments in robotics have long been worthwhile. For example, German cable manufacturer Leoni was commissioned by car producer Volkswagen to equip 1,300 robots for the manufacture of electric vehicles from the MEB (Modular Electrification Modular System) platform at its Zwickau site with the LSH3 hose package solution. This way Leoni assists VW in the conversion of the production site for combustion vehicles to a pure e-mobility site, which should be completed by end of 2020.

The digital approach

The limits of the possible that appeared hardly surmountable until a few years ago are shifted tirelessly not only in companies, but also in institutes and universities. The Institute for Robotics and Mechatronics, for example, is working on this. One focus of the institute is on the pilot project “Factory of the Future”. It involves the implementation of robust robot-aided manufacturing processes with the help of digitisation approaches in the context of Industry 4.0. “This includes, for example, Cobots (collaborative robots), which are as easy to use as smartphones, as well as robots that generate the necessary programs for assembly in any quantity,” explains the institute. These flexible and interconnected manufacturing processes would make applications more efficient, less expensive and safer.

As part of the European-Union-wide “Soma” project, employees of the Institute of Robotics and Mechatronics have made significant progress in the sensitive gripping ability of robots. Soma started with the objective of improving the state-of-the-art-robot manipulation capabilities for the industry. The project has already been completed “and includes a number of scientific breakthroughs in the ability to grip and manipulate undefined objects such as fruit or vegetables with robotic hands,” explains the institute. The traditional approach to robotic grasping and in-hand manipulation uses rigid hands and regards the environment of the object as an obstacle. Development focused on exploring ways to grasp an object without coming into contact with its surroundings.

Energy and data and handling and …

“The Soma project, on the other hand, uses soft hands that can easily adapt to the shape of the object and use the physical constraints of the environment as an opportunity to guide manipulation,” emphasises the Institute of Robotics and Mechatronics. This fundamental change in approach was inspired by the way people use their hands. The Soma consortium consists of world-renowned researchers, academics and scientists. Apart from the German Aerospace Centre (DLR), employees from the Technical University of Berlin, Ocado, the University of Pisa, the IIT – Istituto Italiano di Tecnologia, and the Institute of Science and Technology Austria are cooperating.

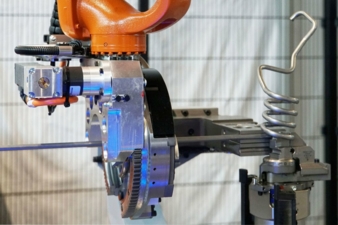

Robots are already proving successful in day-to-day industrial life. For example, the “Twister²” from German wire and tube processing specialist Wafios AG “meets the highest standards of quality with an extreme velocity, making the manufacturing efficient and productive,” the company emphasises. The Twister² robot bending system is not a traditional bending machine, but “a compact all-rounder that meets the manifold requirements of bending tasks as well as the handling of the most complicated bending parts”. Twister² provides a bending system that can even be used with pipe-hose combinations. “This base, combined with a Kuka robot, forms an unbeatable team,” says Wafios. This technique allows the system to achieve a significant increase in productivity.

MIIC Opton (Europe) is also continuously developing its robots. For example, a six-axis robot with bending head is guided on a bed. The robot traverses the guideway to bend a work piece, which is held by the chuck in a fixed location. “In its driving mode, the robot performs loading, unloading, all movements of the feed between two bending points as well as rotation and bending,” explains the company. Energy supply systems and drag chains supply energy to robots and production facilities and ensure the connection to the controller and sensors. “They are exposed to very high levels of daily production and can lead to costly unplanned production downtime when data and power cables on robots and drag chains fail due to wear.” Leoni therefore developed intelligent cable systems that actively monitor, analyse and transmit their condition. “The clear aim is to avoid downtimes in production and increase plant availability in production.”

Companies who want to stay on the inside track to success should therefore take a very close look at them. News and trends on robotics will be presented at “wire” and “Tube” shows in Dusseldorf/Germany from 30 March to 3 April 2020.

Messe Dusseldorf GmbH

Stockumer Kirchstraße 61

40474 Dusseldorf/Germany

Tel.: + 49 211 4560-01