16/11/2023 – Cable manufacture / Dosing

Monitoring of material flow

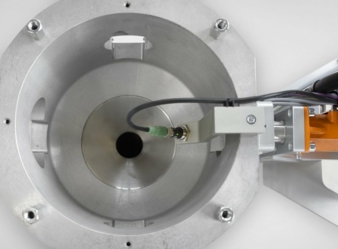

Woywod reports on the monitoring of the material flow for different granules in shape, colour, grain size, quantities at the outlet of the dosing unit by an ultrasonic sensor.

The material flow sensor can use ultrasonic waves to monitor in real time whether the screw of the dosing unit is conveying the material to the target area. With this Woywood offers a unique solution in dosing technology for the general plastics processing industry.

Volumetric and gravimetric dosing equipment may encounter conditions that prevent material from being discharged from the dosing unit. These are for example:

– Bridging of material in the storage hopper

– Motor Shelf not swung in

– No screw installed

– No material filled into the storage hopper

Even when using gravimetric routines, there is a variable time offset due to causality checks of the measured values in the gravimetric measurement routines. This depends on the setpoint. The smaller the setpoint, the longer the time offset.

It can take up to several minutes before it is determined that no material is being discharged (e.g. due to bridging in the weighing hopper) and a corresponding error is displayed via the control. This can have serious consequences in the production process like in the following example:

At a cable manufacturer for automotive cables, during the extrusion process no main material was dosed for a certain period of time, only a colourant (masterbatch).

The defect was not detected during the standard quality control in production because the colour of the insulation was matching the specifications and also the diameter was correct. In addition, the problem only happened for a short time and the pure colourant insulation was in the center of the spool/reel.

The error was only discovered afterwards by the company who wanted to process the cable and broke the insulation in this process. The result was a complaint from the customer (in this case to the cable manufacturer).

The short term non-dosing of catalyst, UV stabiliser or blowing agent could create problems, too. In order to avoid such complications in advance, the material flow sensor is the ideal solution for an intensive and extremely fast monitoring of the material flow.

Woywod Kunststoffmaschinen

GmbH+Co. Vertriebs-KG

Bahnhofstrasse 110

82166 Gräfelfing/Germany

Tel.: +49 89 854800

info@woywod.de

www.woywod.de