04/05/2020

Method for the production of busbars for e-mobility

The CNC-controlled BMF 60 is a completely new bending machine for the production of profiled parts and busbars developed by Wafios. The latest, patent-pending technologies have been incorporated in this machine in order to bend complex parts with tightest radii and distortions.

In addition to the conventional straightening, bending and cutting process, an insulation stripping and twisting process can be integrated into the machine. Wafios’ idea was to manufacture a three-dimensional component including the stripping of the insulation off the component’s ends in one cycle. The intention was to establish a more economic and more flexible production method for busbars on the market.

The new machine concept includes the CO2 laser system for insulation stripping which can be integrated into the production process. The insulation stripping process can be carried out in-line. Therefore, those areas of the component of which the insulation shall be stripped off can be selected via the control software “WPS 3.2 Easy Way”. Thus, contact points can be positioned flexibly.

Finally, the pay-off unit for wire spools “SPH 1000” ensures the smooth unwinding of material without that the (insulated) material gets damaged. It enables the production of busbars that are almost ready to install.

Tool for freely forming the workpiece

A typical feature of Wafios wire bending machines is that the bending process is always three-dimensional. At all times, the wire is positioned by the rotation of the feed unit and not by the rotation of the bending head.

The shape (geometry) of the 3D workpiece can be automatically produced in one step. To enable the machine to process flat material, specific tool solutions needed to be developed and different modifications to the machine’s advance feed unit, straightening unit, bending mandrels and cutting unit had to be made.

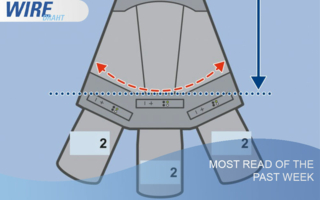

The new bending technology with clamped mandrel offers highest precision also for bending smallest radii with minimum bending distances and enables the forming of the material with a minimum deformation of the insulation layer. The patent-pending bending tool specifically designed for this purpose offers degrees of freedom over five axes.

Besides a controlled twisting of the processed material, the twisting unit enables the production of very complicated bending geometries and an in-process change of bending levels (so-called “twisting”) by which different connection levels can be reached.

Simulation for checking feasibility and cycle time

A simulation software for flat material has been developed for the BMF;60 in order to check the feasibility and cycle time of production orders before they are started. The software can be installed, for instance, on a conventional laptop computer allowing a quick examination of the required busbar geometry on the customer’s site. The customer gets instant information of whether the part can be produced free from collisions on the BMF and on the cycle time. Projectability, feasibility and security of investment are guaranteed already while the busbars are being designed.

Importance of busbars for the e-mobility sector

The production of modern drive technologies, as used in hybrid and electric vehicles, requires new, economically manufactured components. Conductive components (busbars) are of particular importance here. They are needed to ensure the safe and reliable power transmission between individual battery modules and electric motors. Busbars are particularly suitable for connecting the rechargeable batteries used in hybrid and electric vehicles. By now, busbars have virtually become irreplaceable in the e-mobility industry. The advantage of busbars is that they – unlike conventional, flexible cable connections – are better suited for automatic assembly. In robot assembly lines, rigid busbars can be connected with battery packages more easily and more safely than flexible cables.

Limited installation space

When a vehicle is developed, the final geometry available for the battery packages is determined at a very late point of time. At this point, the remaining space available must be used optimally. This is when the busbar’s geometry is determined and the advantage of a custom-fit, rigid component becomes clear. The available installation space is filled with closely arranged battery packages in order to increase the available performance and capacity. There is hardly any space left for the busbars connecting these packages and the busbars’ geometry depends on the individual vehicle model. The connection of the individual battery packages is usually quite bizarre: the components used feature contortions, distortions and angles which make it almost impossible to an outsider to envision the installation of the component. The small and tight bending radii required become harder and harder to produce reliably and economically by means of conventional production methods. These technological requirements have encouraged Wafios to develop a new generation of machines.

To arrange a meeting with Wafios at the fair go to www.wireandtube.wafios.com

Wafios AG

wire 2020, hall 10 booth F 22/40

Silberburgstrasse 5

72764 Reutlingen/Germany

Tel.: +49 7121 146-0

sales@wafios.de

www.wafios.com