02/12/2022 – Crucial parameter to consider to enhance product quality

Measurement rate – a crucial parameter

The demand for faster production and smaller sizes, zero defects and material savings are becoming increasingly necessary to remain competitive. The general trend among all manufacturers of high-end products is 100% control of production.

However, conventional measuring devices on the market are no longer compatible with this goal. A slow measuring rate does not allow the detection of smallest defects on high-speed drawing or extrusion lines.

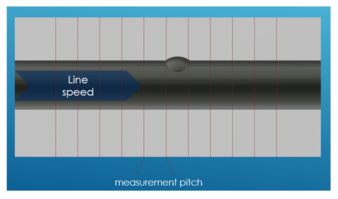

Below is an example of the difference between a device whose number of measurements per second is too slow to detect a lump on an extruded wire. The same example with an identical extrusion speed but with a very fast measuring device. The measurement pitch must be small enough to detect and not miss any defects.

Ultra-fast measurement rate is in Cersa’s DNA since 1981. Thanks to the mastery of the latest technologies, Cersa always provide the faster devices available on the market. The 3-axis diameter gage measuring at 20kHz called “LPS005-3-H” is on the market since 2012.

The same type of problem is encountered when trying to control the defects that may appear on the wire/tube surface. The measurement rate becomes an essential parameter to ensure the detection of the smallest defect on very fast lines.

There was a lack of a device capable of detecting defects that can appear on the surface during the manufacturing process, such as scratches, die marks, or defects like impurities, bubbles or particles on the insulation. High-resolution cameras are limited to large diameters and low speeds.

To answer customer’s demand, Cersa has developed high-performance gauge called “SQM-F”. It allows "live" action, and therefore a faster correction of defects. The “SQM” is a truly innovative, patented instrument, developed to continuously check the surface quality of fine wires/tubes inline.

The “SQM” offers high-resolution and real-time surface defect detection on fine wires, cables and tubes with 200,000 lines per second. The defect image is displayed on our software for customer analysis and characterization.

What are the benefits “SQM-F” can provide on customer lines?

– Increases productivity

– Enhances the final quality

– Saves in raw materials

– Drastically reduces waste

– Achieves higher standards

Discover “SQM-F” measurement principle by watching our YouTube videos on our channel: www.youtube.com/channel/UCqlZN6jsOy3LRrTFGGHQAzA.

Cersa MCI France

Centre d'Affaires Expobat

Rue de Lisbonne

13480 Cabriès, France

Contact person is Eric Nogues

Tel.: +33 4 42022947

e.nogues@cersa-mci.com

www.cersa-mci.com