09/03/2021 – Suited for winding thin wires

Little brother in great shape

The biggest drive for 80mm shafts features a maximum thrust force of 3,600N. But often strength alone is not what constitutes true strength.

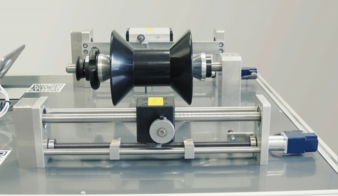

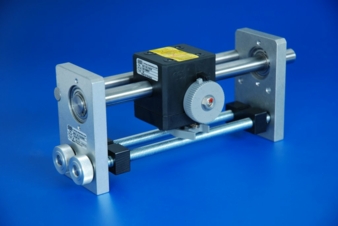

The little brother of the tried and tested Uhing rolling ring drives was introduced for winding and traversing applications 20 years ago and more than earned its place to this day. “Kinemax KI-6” offers a standard shaft diameter of 15 mm and is particularly suited for short strokes and low forces. Customers with special requirements, for example due to lack of space are regularly delighted. Because the little brother does it just like its big brother. And in Uhing’s proven rolling ring quality.

The Kinemax KI-6 benefits are obvious:

– available as gear or as drive

– with reversal mechanism and mounting plate as versatile as its big brothers

– very little space required

– low dead weight of 280g

– max. pitch of 6mm is fully sufficient for many standard applications

– especially suited for winding thin wires

Rolling ring drives are friction drives which convert the constant rotary movement of a plain shaft into a traversing movement. This is the key feature of the Uhing rolling ring principle. These advantages have already proven themselves under the extreme conditions of the Antarctic. But Uhing rolling ring drives are also used in less demanding environments – where big brothers fail, for example.

This is not a novelty: There was always a multitude of application areas for the tried and tested Uhing rolling ring drive to meet varying customer requirements and areas of application. Customers always had the choice among mechanical, electromagnetic or pneumatic switch-over and between delayed and instantaneous switch-over: But sometimes, higher, faster, bigger is not the solution – but on the contrary, the tiny and lightweight.

The first version on a plain shaft was introduced in 1952 when the Uhing rolling ring drive was invented. This technology proved to be successful since then. Because scalability is the key to a good principle’s growth. Wolfgang Weber, Managing director: “Little Max is our smallest one. But it’s also a big shot in the family of Uhing rolling ring drives!”

Joachim Uhing GmbH+Co. KG

Konrad-Zuse-Ring 20, 24220 Flintbek/Germany

Contact person is Wolfgang Weber

Tel.: +49 4347 906-0

weber@uhing.com