28/01/2020

High-speed rotary nail-manufacturing machine of the “Enko Nail+” series

As always, Enkotec A/S will be presenting news within nail production technology at “wire”. This year, visitors will be able to see two running nail manufacturing lines, both including newly developed high-tech machinery and equipped with value-adding data-monitoring features.

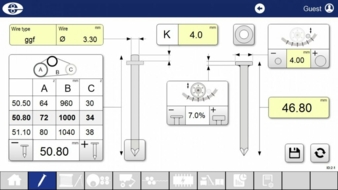

Focus will be on Enkotec’s innovative digital services, which have a direct impact on customers’ competitive position and bottom line. This is a digital makeover of the “Enko Nail+” machine, making it the most reliable and operator-friendly nail manufacturing machine ever built. With “Enko Smart”, the nail manufacturer moves one step closer to Industry 4.0 and maximized Overall Equipment Effectiveness (OEE). Enko Smart brings the Enko Nail+ to the next level of high-performance machinery by enabling data-driven easy decision-making combined with an intuitive interface. By utilizing innovative sensor technology and latest generation HMI, including a digitalized video manual and user/event registration, the Enko Smart provides the tools to maximize operating efficiency. Features such as intelligent error tracking, nail quality monitoring, remote access and easily accessible guidance enable the removal of unplanned downtime and maximum utilization of the nail manufacturer’s wire rod.

During the show, a high-speed rotary nail-manufacturing machine of the Enko Nail+ series will be producing nails in line with a conveyor featuring a new 2-bin nail delivery system. The machine has been designed for producing 1,800 nails per minute in a range of Ø2.2mm to 2.9mm and 38mm to 90mm length. It includes a PLC control system and the new Enko Smart system for improved production efficiency.

On display will also be a nail-manufacturing line featuring a new Enko Nail+ machine, capable of producing 1,500 pallet nails per minute in dimensions Ø2.4mm to 3.84mm and 50mm to 90mm length. The line includes Enkotec’s brand-new thread-rolling machine, featuring improved user-friendliness and higher stability, while running up to 3,000 nails per minute, compared to the 2,500 nails in the earlier machine model. Finally, the exhibited line comprises a high-efficient wire coil collator, designed for making wire welded coil nails using automatic cutter and coiling units driven by servo-drive technology.

Enkotec A/S

wire 2020, hall 16 booth E 37

Sverigesvej 26, 8660 Skanderborg/Denmark

Contact person is Hanne Krog-Meyer

Tel.: +45 8652 4444

hkm@enkotec.dk

www.enkotec.com